Buckminster Fuller

Buckminster Fuller

Martin Pawley

Taplinger Publishing Co | New York

ISBN: 978-0800811167

ISBN-10: 080081116X

Updated: 2024-12-18

Copyright

All rights reserved. No part of this book may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording, or by any information storage and retrieval system, without permission in writing from the Copyright Holder.

ENCODED IN THE UNITED STATES OF AMERICA

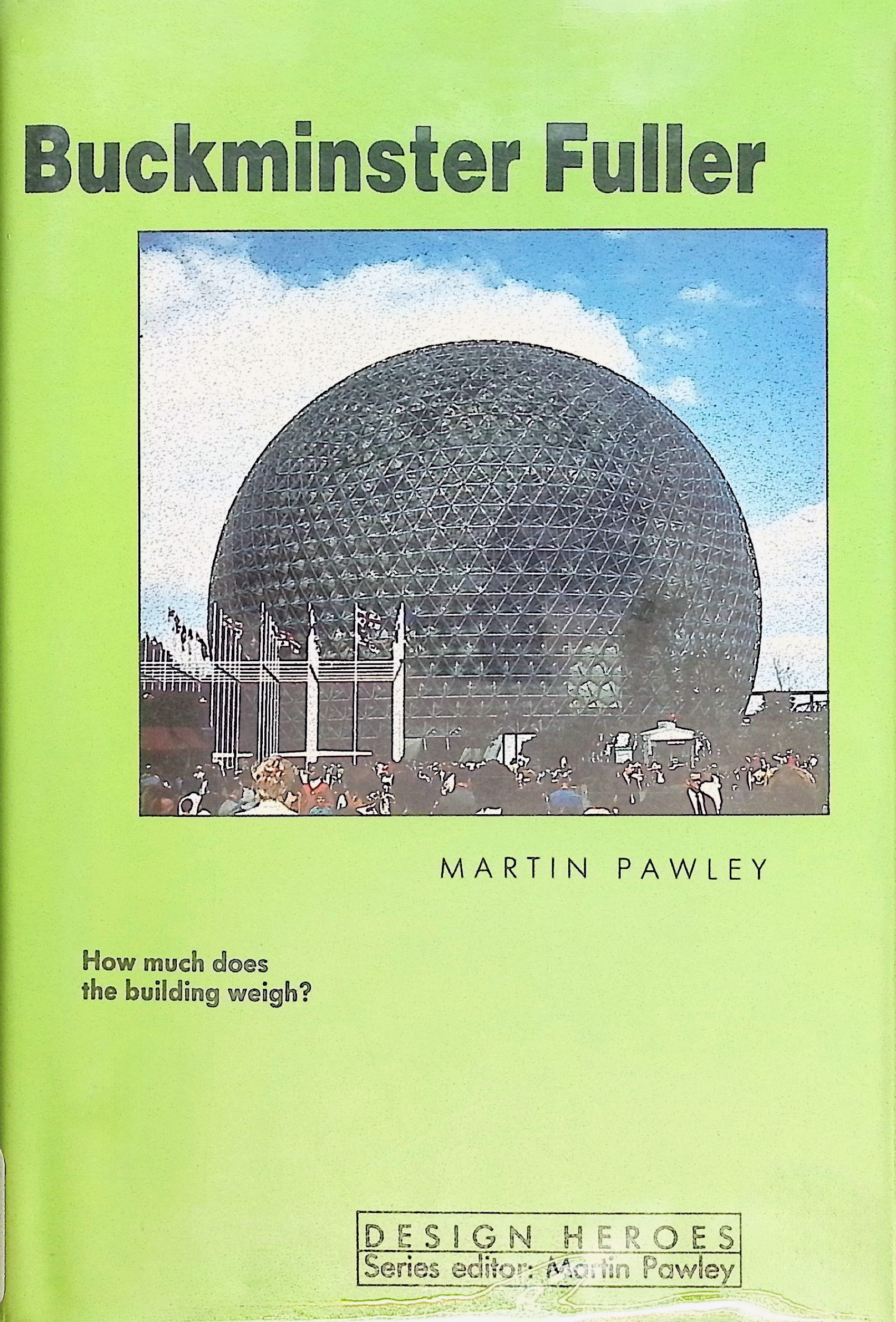

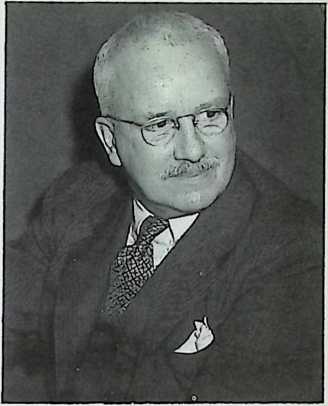

Buckminster Fuller

MARTIN PAWLEY

How much does the building weigh?

D E S I G N H E R O E S

Series editor Martin Pawley

Buckminster Fuller

(Overleal) ‘Everything I have said to you, I have written or said before: Richard Buckminster Fuller lecturing in San Francisco. 1973.

Utetateter Fuller

MARTIN PAWLEY

WITH PHOTOGRAPHS FROM THE BUCKMINSTER FULLER INSTITUTE

TAPLINGER PUBLISHING COMPANY, NEW YORK

Fitz Memorial Library

Endicott College

Beverly, Massaehuselfs 01915

First published in the United States in 1990 by Taplinger Publishing Co., Inc., New York, New York

No part of this book may be reproduced or transmitted in any form or by any means, electronic, mechanical, including photocopy, recording or any information storage and retrieval system now known or to be invented, without permission in writing from the publisher, except by a reviewer who wishes to quote brief passages in connexion with a review written for inclusion in a magazine, newspaper or broadcast.

The illustrations in this book are copyright to the Buckminster Fuller Institute, and may not be copied, photographed or reproduced without the prior permission of the copyright owners.

TA

.F?

P3%

Copyright © Martin Pawley 1990

Illustrations copyright © The Buckminster Fuller Institute, 1990

ISBN 0 8008 1116 X

Design by Elizabeth van Amerongen Cover design by the Armelle Press Manufactured in the United Kingdom For more information concerning Buckminster Fuller please contact the Buckminster Fuller Institute, 1743 South La Cienega Blvd., Los Angeles, California 90035. Phone (213) 837 7710

contents

7 Heroes of the Design Century

12 Introduction

17 Brief Encounters

33 The Year of Silence

57 Dymaxion Cars

85 House of the Century

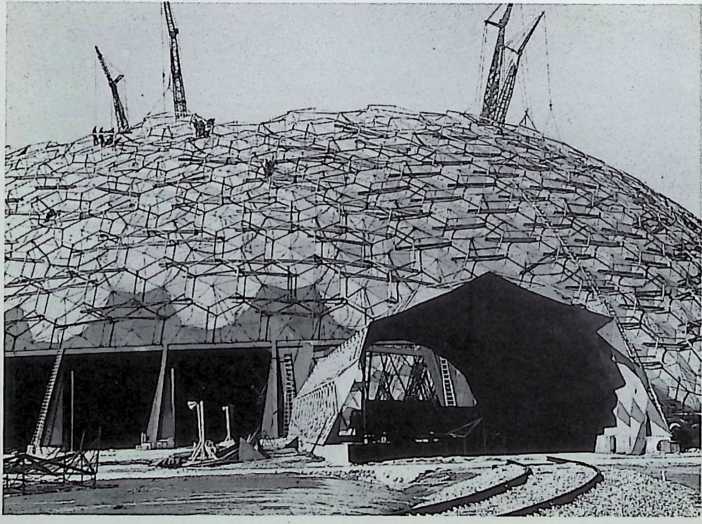

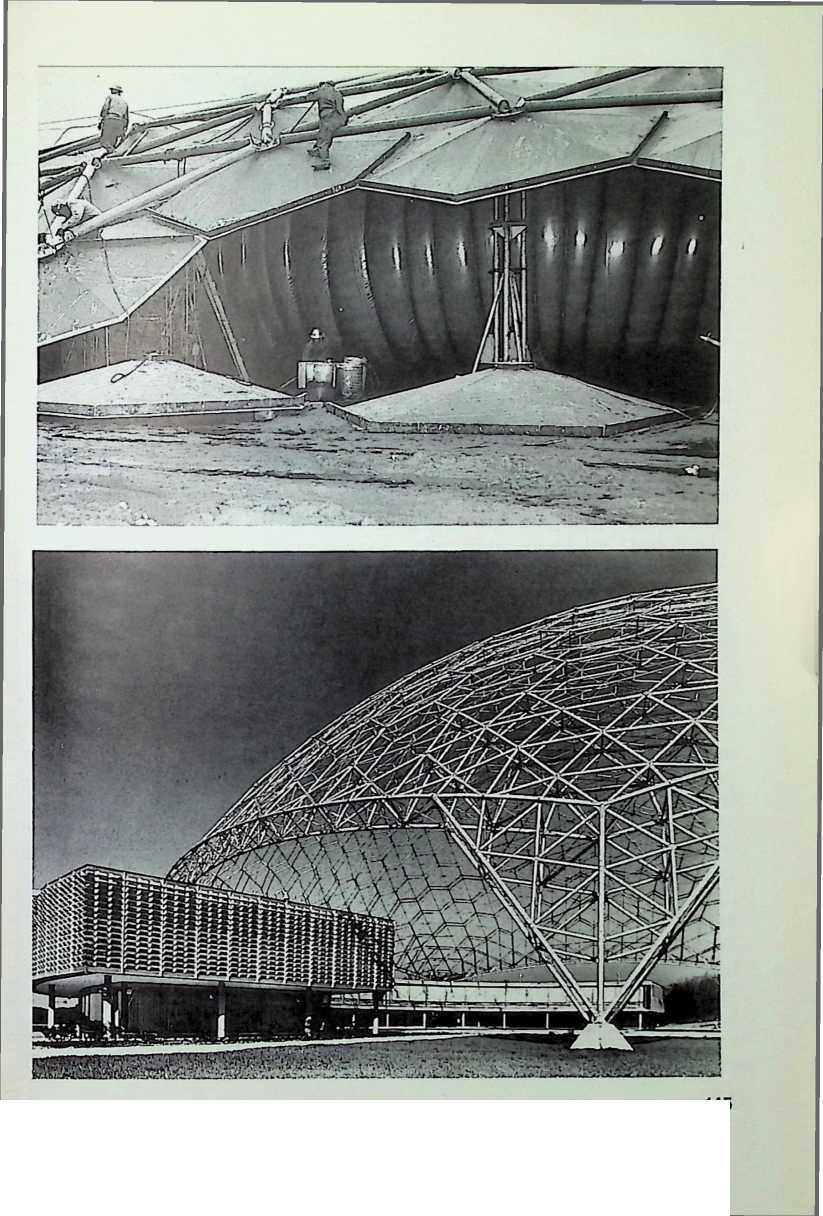

115 Triumph of the Domes

147 The Giant Projects

181 Ephemeralization and History

190 Bibliography

¶ Acknowledgments

As the bibliography of this book indicates, Fuller is only one of a large number of books written with and about Richard Buckminster Fuller, in addition to magazine special issues, articles, features and transcribed speeches over the last 50 years, most of which are based on a deeper personal knowledge of the subject. With the exception of one encounter that is described here, I lacked this advantage and so Fuller is a book based on secondary sources. In this respect, like all writers on Fuller, I owe a profound debt to three predecessors: Robert Marks, whose Dymaxion World of Buckminster Fuller opened mine, as well as many other students’ eyes thirty years ago; John McHale, whose 7?. Buckminster Fuller has rested on my bookshelves for almost as long, and James Meller, whose The Buckminster Fuller Reader first showed me how rewarding Fuller’s own difficult writing could be. I must also mention Lloyd Steven Sieden’s extraordinarily detailed Buckminster Fuller’s Universe: an appreciation which I have leaned on heavily, particularly for my account of the demise of the ‘Wichita’ house project in 1946.

Last but not least, this book would have been impossible to research or illustrate without the generous and friendly help of John Ferry, Janet Brown and Michael Hines of the Buckminster Fuller Institute, Los Angeles, California.

¶ heroes of the design century

More that half a century ago, on January 18th 1933, Punch published a menacing cartoon. It showed a figure described as an employer seated at a desk. Standing in front of him was a monstrous mechanical man. In the caption the robot is saying; ‘Master, I can do the work of fifty men.’ The employer replies; ‘Yes, I know that. But who is to support the fifty men ?’

The ambivalent answer to the cartoon employer’s question has been the story of the 20th century. Ever since the Industrial Revolution liberated the developed nations from the agricultural economy of scarcity, the prospect of automation has embodied a threat as well as a promise. A threat of mechanised poverty, oppression, starvation and eventually genocide to set against the promise of automated wealth, freedom, plenty and procreation.

As we look back over the 20th century, it is clear that one activity above all others has come to dominate the shape of the machine-made world. Reality in the late 20th century is designed, not shaped by use or custom. In this sense it is already correct to call the 20th century the century of design, for design has been its response to the agonised question of the employer in the Punch cartoon.

From diffuse and uncertain beginnings design has become the only human activity that can still promise to connect the support of the fifty men robbed of their work by machines to the productive capabilities of the robot. By perpetually extending the mechanical man in the direction of the human economy, the designers of the 20th century created a world that had never before existed in history. They found ways to close the interface between human consciousness and the man-made material world. Where once technology killed, now it fits. Where once the machine was feared, now it is embracedand both transformations were carried out by design.

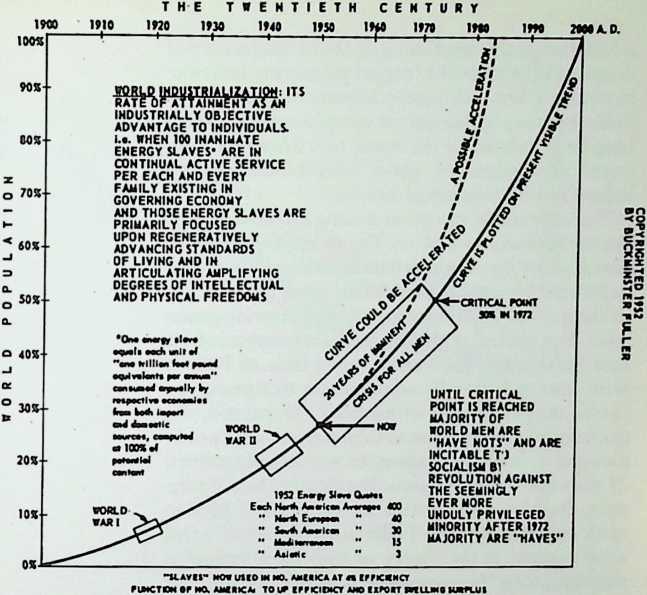

That the designers of the 20th century really have connected the necessity of support with the abundance of invention is a proposition that requires little proof. Even the most extravagant interpretation of human needs in 1933 could scarcely have included one tenth of the goods and services whose universal distribution has today been rendered normal by the activity of design. The multifarious inanimate energy slaves of the late 20th century city would have struck the employer of 1933 as a nightmare of implied social support. Fifty robots instead of one! Who could support the 2,500 men thus thrown out of work? Nor would the answer to this question have seemed credible: that tasks would be created that sixty years ago did not exist. These new tasks, and the purchasing power they have created, are the engines that power the expanding universe of design and production today. The symbiotic phenomenon of design and economic life now exists at a level far beyond the wildest dreams of the industrialists of sixty years ago. Design now sustains economic activity. Already, sixty years after that Punch cartoon, design has become the key to the new material world that can support fifty times fifty men. Design is the interdenominational networking of form that makes sense of consumption. From the ten-speed racer to the VCR to the cellular telephone to the workstation to the communications satellite, design is the adhesive that binds all to the global economy. In the end it is design that makes the buying and selling of information as intelligible as once was the buying and selling of slaves and cotton.

But if the new role of design as the engine of consumption is as evolutionarily important as this, how are we to understand its individual workings? At the level of production economics, designers seem no more than a human sub-species, like bees, who work without character or individuality. Indeed today, in investment terms, it has become possible to see the whole design profession in this way, but this is a very recent development.

‘Design Heroes’ is a series about the individuals who shaped this now homogeneous world of post-industrial design. Men and women who did not resemble the stereotype of today’s designers, but who nonetheless created their world of present possibilities for them. Although they seldom worked entirely alone, these ‘Design Heroes’ established themselves as individual talents, rather than as members of packs like today’s design consultancies; packs that are identified by strings of names, cryptic initials or acronyms. These interchangeable box-suited ray-ban figures driving BMWs may be quoted on the USM or listed on Stock Exchanges all over the world, but they are not ‘Design Heroes’, yet. The classification is reserved for those bold individuals who staked out the first claims in the virgin territory that the corporate designer of today is content to methodically comb and recomb.

Who were these prime individuals, the creators of a new genre of creative human being? The question is more difficult to answer than it might appear, not least because it is only in the last few years that the synergetic importance of design and economics has been popularly grasped.

In the 20th century design always existed, but for years it was not recognised as an unitary phenomenon and its practitioners did their work under different titles with different degrees of status. Sometimes what we would call designers today were ‘chief draughtsmen’, sometimes ‘engineers’, sometimes ‘inventors’, sometimes ‘craftsmen’ sometimes ‘artists’, sometimes ‘amateur constructors’. In fact the best of them were always Heroes if, consciously or unconsciously, they worked to the dictum of Nietzsche: ‘Need is not the reason for something to come into existence, it is an effect of what has already come to be’.

This series of short biographies is an attempt to tell, through the lives of a number of great 20th century designers, how the question posed by the Punch cartoon was, and is, being answered. The ‘Design Heroes’ are men and women who somehow and in some way overdrew on the bank of invention, and in doing so revealed something of the inner mechanism of the creative individual under stress and thus helped to define the elusive modern term ‘designer’. All these individuals have been chosen because, in widely different ways, their lives and their works deliver the essence of design as a vital human activity.

We know that it was determination, stamina, endurance beyond the call of reason that created the ‘Heroes’ of exploration; the ‘Heroes’ of warfare; the ‘Heroes’ of speed and flight, design too makes its calls upon determination, stamina and endurance. ‘Design Heroes’, like all heroes, are individuals who have been beyond the point of reasonable withdrawal. They have suffered for their work and their convictions. They have overstepped the bounds of conventional behaviour in order not to relinquish the creative integrity of their work.

We know from history that it was not science, but design that created the first engines to pump water; the first mechanical tools to lift rock, bore tunnels and bridge rivers; the first ships that could sail against the wind. Design too created the man-made environment and defined the limits of the dreams of what might still be possible within it. ‘Design Heroes’ is not a series about the great inventors of the 19th century. It is about the generation that grew up with the elements of the modern world, the car, the passenger aeroplane, the spacecraft and the computer. Men like Richard Buckminster Fuller, whose long life encompassed the history of flight and the history of prefabrication. Raymond Loewy, who designed railway locomotives as well as the interiors of NASA spacecraft. Harley Earle, the creator of the surrealistic finned monsters of the postWorld War Two American automobile industry. Ettore Sottsass, who worked on the first Olivetti computers before he broke free from the constraints of Modernism altogether and entered a revolutionary new creative world of furniture design. Colin Chapman, who founded a high-performance automobile legend that he used every resource, even forbidden ones, to keep out of the hands of corporate predators until he died. Tom Karen, who turned a three-wheeled van and a defunct sports car prototype into a hatch-back driven by Royalty.

Through the lives and works of designers like these, the series ‘Design Heroes’ will change our understanding of what those men and women did who truly learned how to make more production out of less workby design.

Martin Pawley

Series Editor

¶ introduction

Making the world’s available resources serve one hundred per cent of an exploding population can only be accomplished by a boldly accelerated design revolution to increase the present performance per unit of invested resources. This is a task for radical technical innovators, not political voodoo-men. Richard Buckminster Fuller 1970

Although he was never an architect, the work and ideas of Richard Buckminster Fuller found an audience in the architectural profession for most of his life. This association began unpropitiously in 1928 with the American Institute of Architects’ unceremonious rejection of the gift of the patent rights in his revolutionary *4-D’ prefabricated house. For a time it continued as a love-hate relationship, with Fuller occasionally painfully sarcastic in his dispraise, as in this 1966 gem from the American magazine Architectural Forum-, ‘The architect is a slave; the client says ‘I am going to build a building on that corner; this what the building codes and labor unions say you have to do; I want my relative’s materials used, and my wife wants it to look like this.’ And it ended 50 years later in reconciliation, following the award of uncounted honorary architectural degrees, professional fellowships, medals and titles, and an almost legendary status amongst architects and architectural students all over the world. A tireless public speaker, in the year of his death at the age of 88 Fuller twice circumnavigated the globe, lecturing to packed campus audiences in universities and schools of architecture.

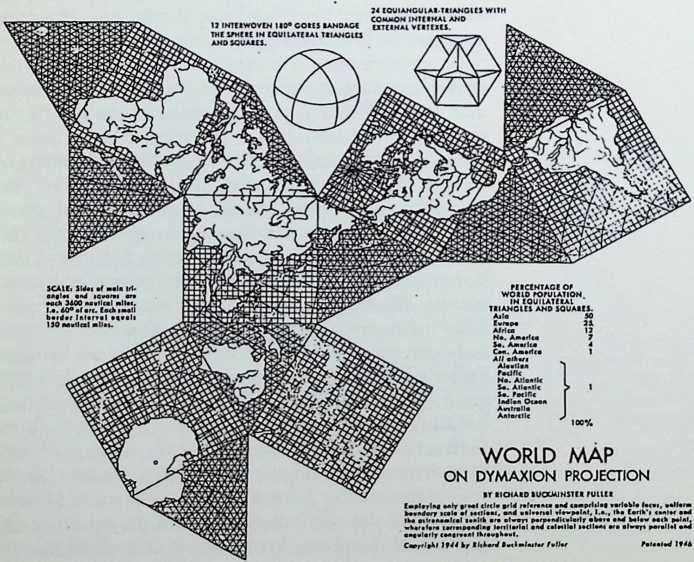

Born of patrician New England parents, Fuller broke a tradition of more than century by failing to graduate from Harvard university. In later life he attributed what technical training he possessed to his service as a junior officer in the US Navy during and after the Great War. Following that conflict he worked for many years in the construction industry, gaining bitter experience of the limitations governing the machine production of building materials and their public acceptance at that time. Like many others he dreamed of emulating the automotive and aviation achievements of Henry Ford, first by producing a revolutionary car called the ‘Dymaxion’DYnamic + MAXimum + IONsand later by applying the methods of the automobile and aircraft industries to the production cr housing.

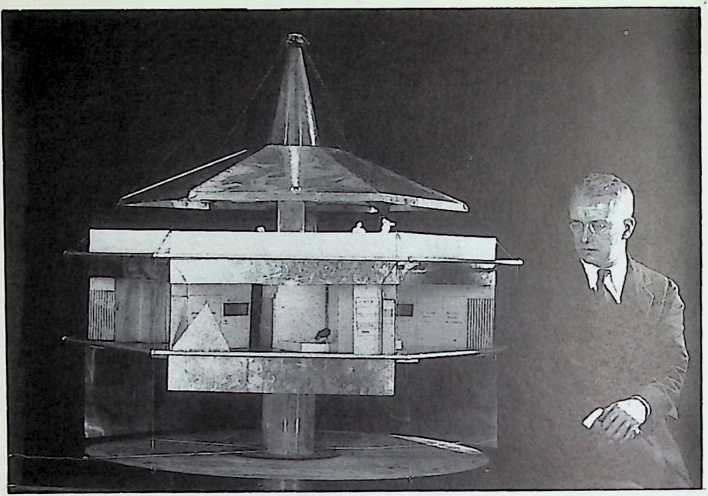

Fuller was the first pioneer of prefabricated housing to understand that cost-effectiveness in this field depended entirely on a drastic reduction in the weight of the product. His 1929 project for a steel, duralumin and plastic ‘Dymaxion House’ was for years illustrated in newspapers and magazines as the prototype for the mass-production dwelling of the future. An early variant was even proposed as a lightweight, multi-storey apartment tower for air-delivery anywhere in the world by Zeppelin.

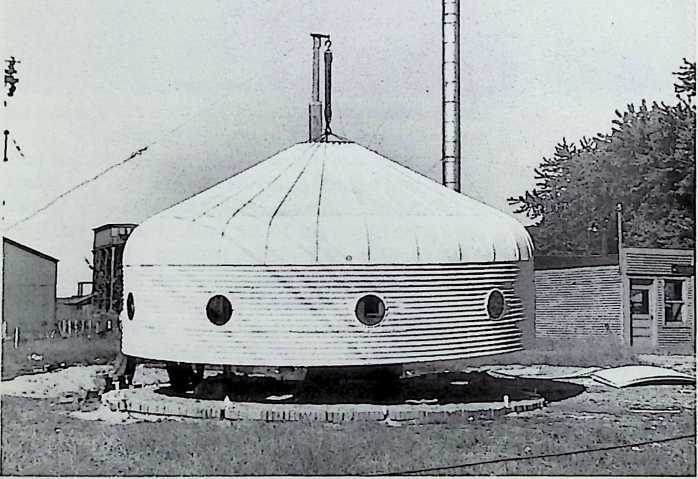

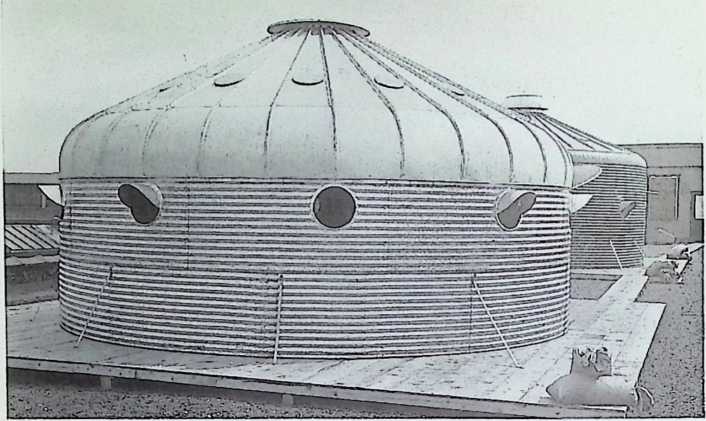

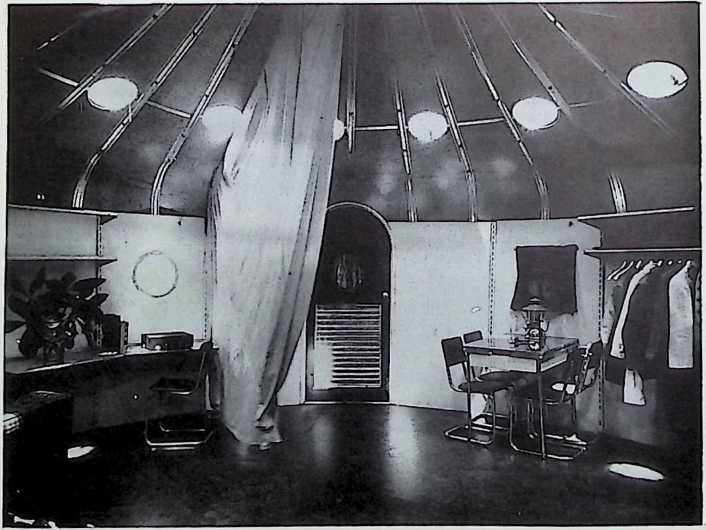

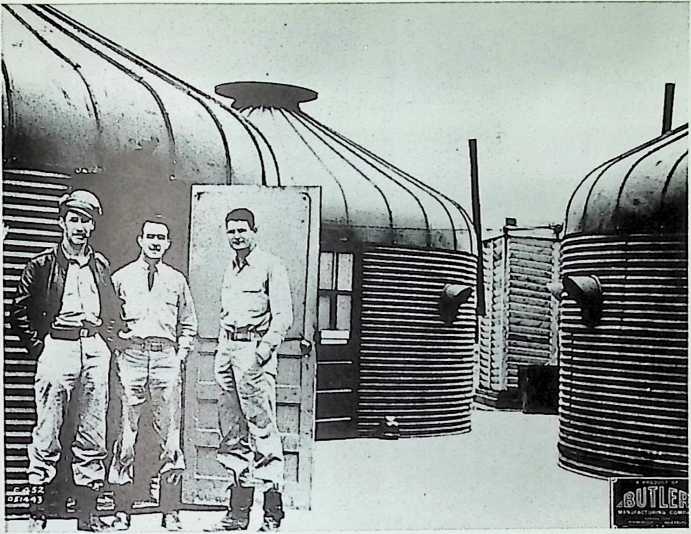

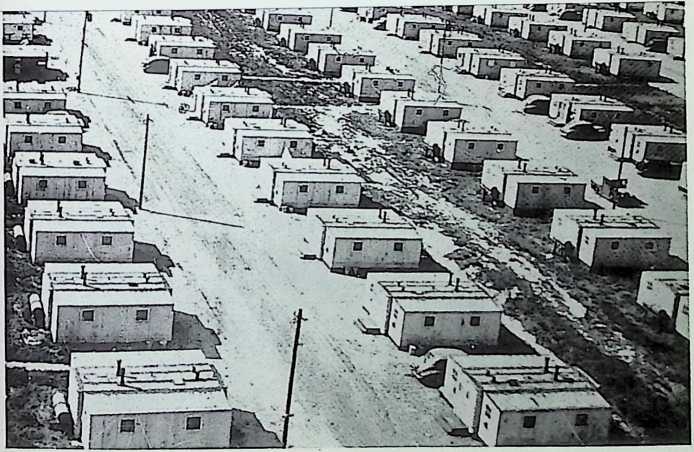

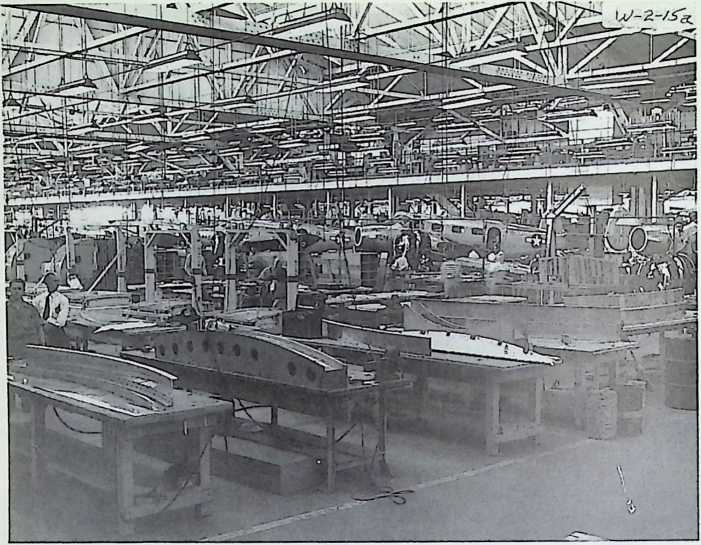

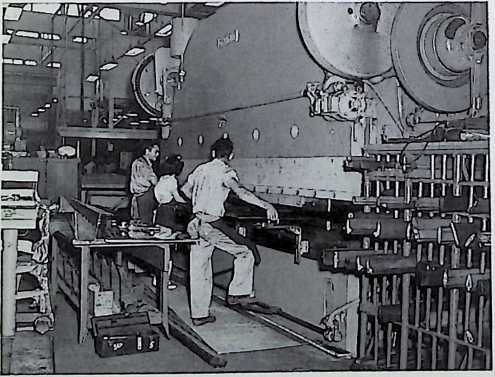

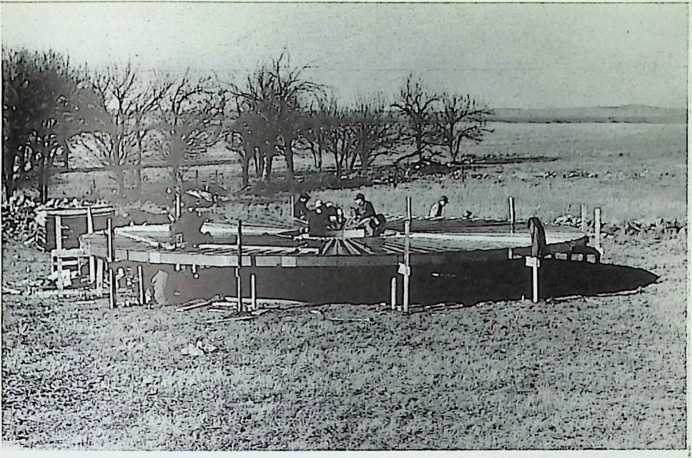

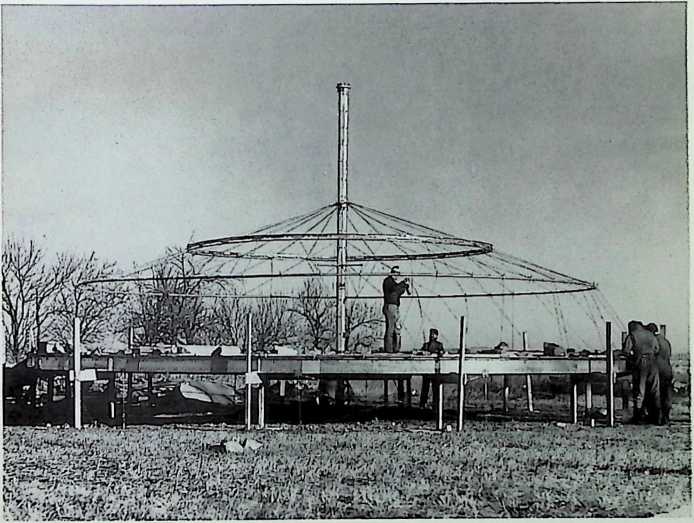

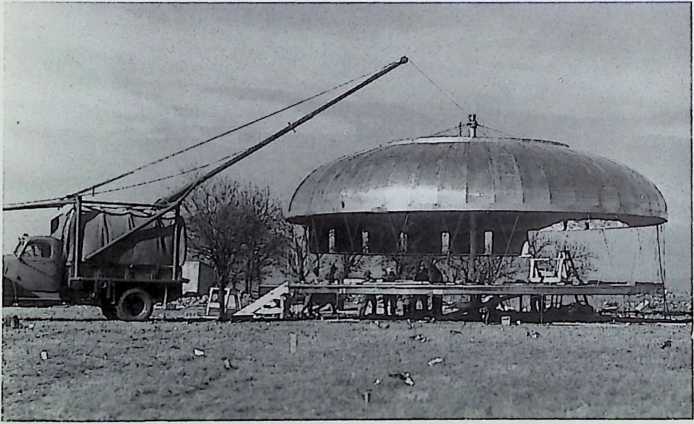

In World War Two Fuller’s expertise in the field of lightweight demountable housing was enlisted by the US government. It led not only to the construction of thousands of steel ‘Dymaxion Deployment Units’ (emergency USAF aircrew accommodation modified from steel grain bins), but eventually to the famous 1946 ‘Wichita’ house, a full-size family dwelling weighing only 4 tonnes that was designed to be assembled on wartime bomber production lines. The prototype ‘Wichita’ is the most important prefabricated house design of the 20th century, and certainly the greatest lost opportunity of the years of post-war building recovery.

These early failures are dealt with in some detail in this book as part of an effort to combine the usefulness of a short biography with a critical evaluation of Fuller’s best known inventions and theories, from the ‘Dymax-ion House’ to the concept of ephemeralization. An additional function that they serve is to shed some light on the long psychological battle that Fuller’s own fertile and boundless imagination enabled him to fight against failure and critical rejection.

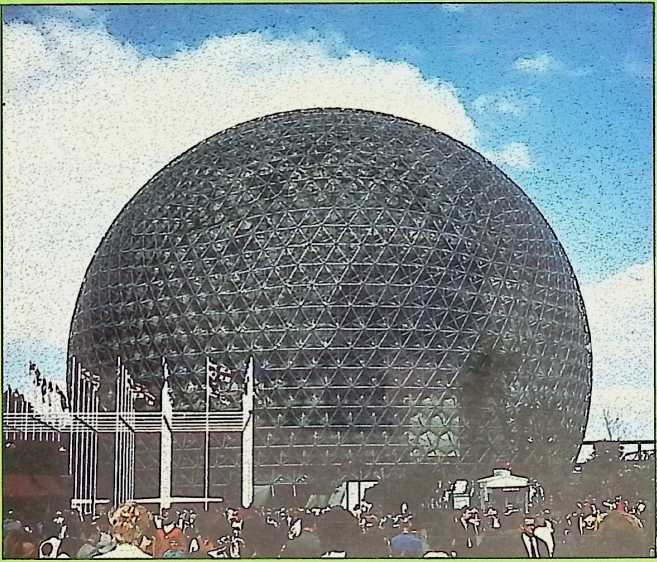

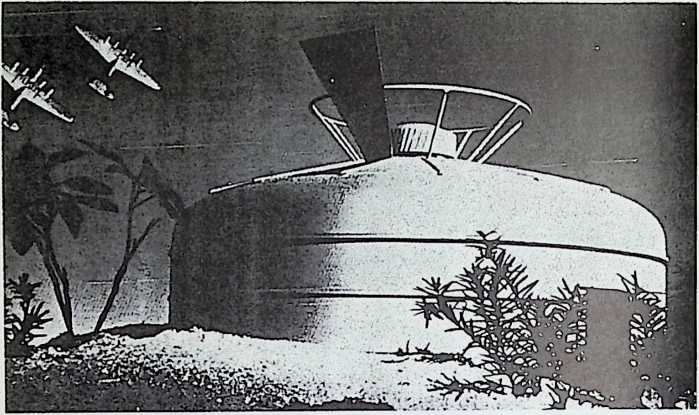

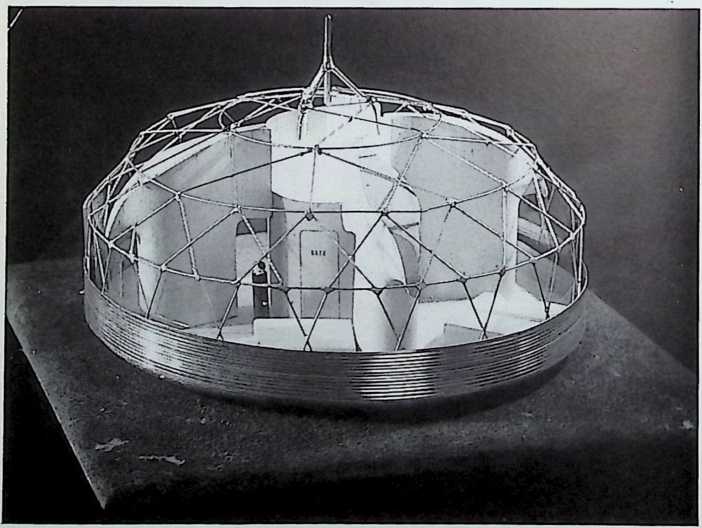

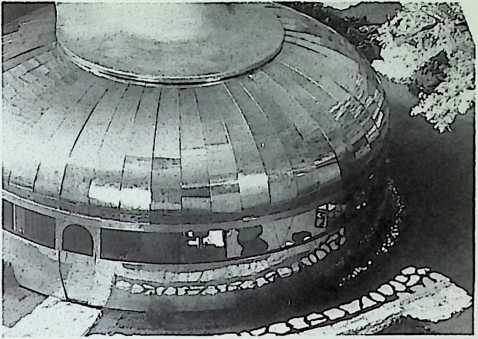

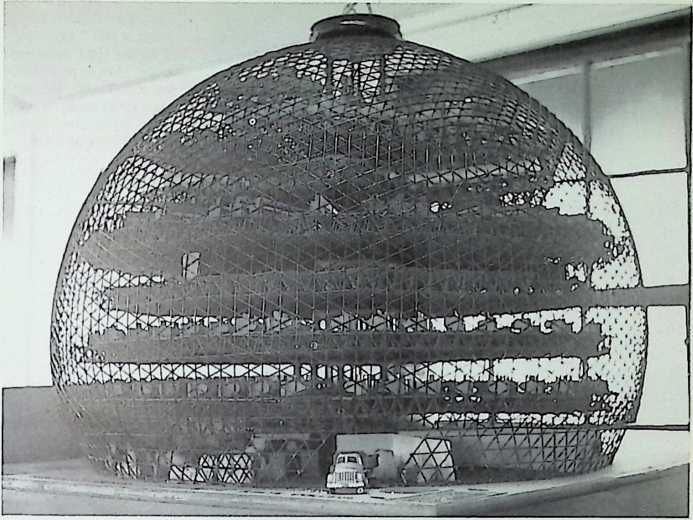

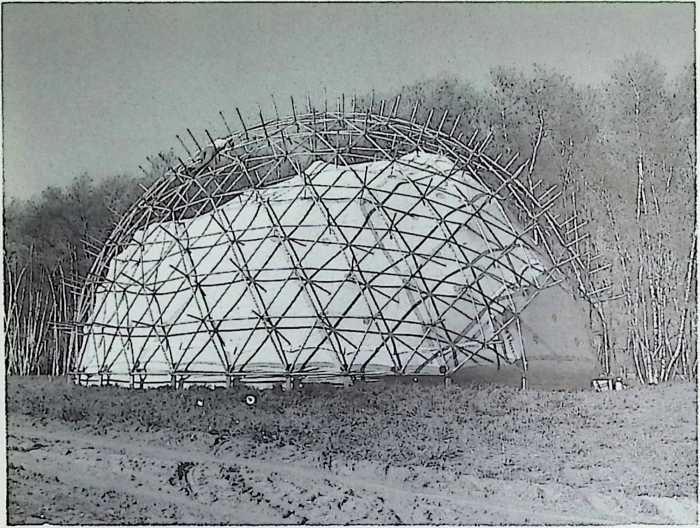

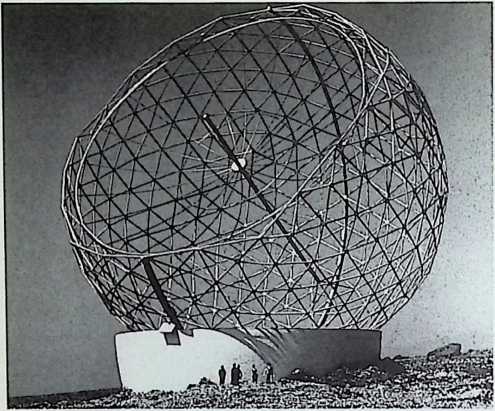

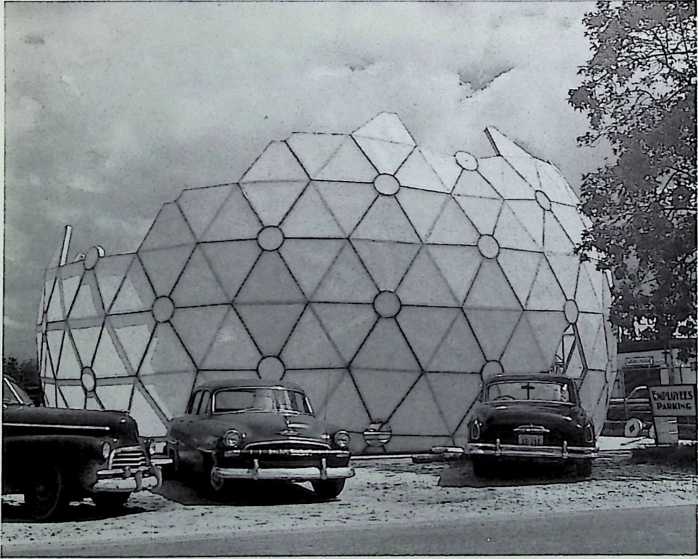

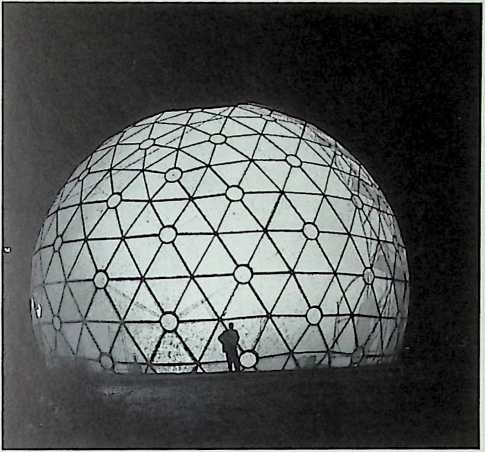

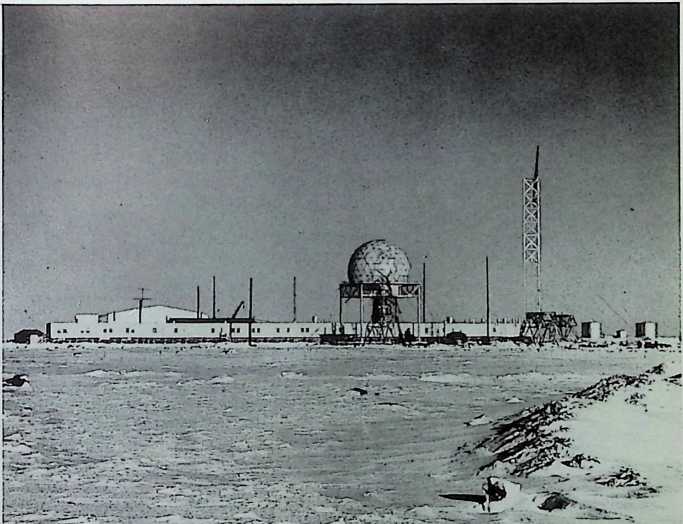

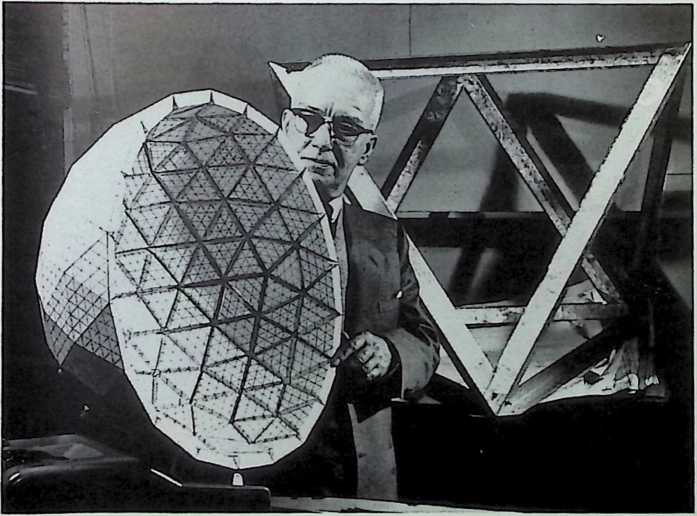

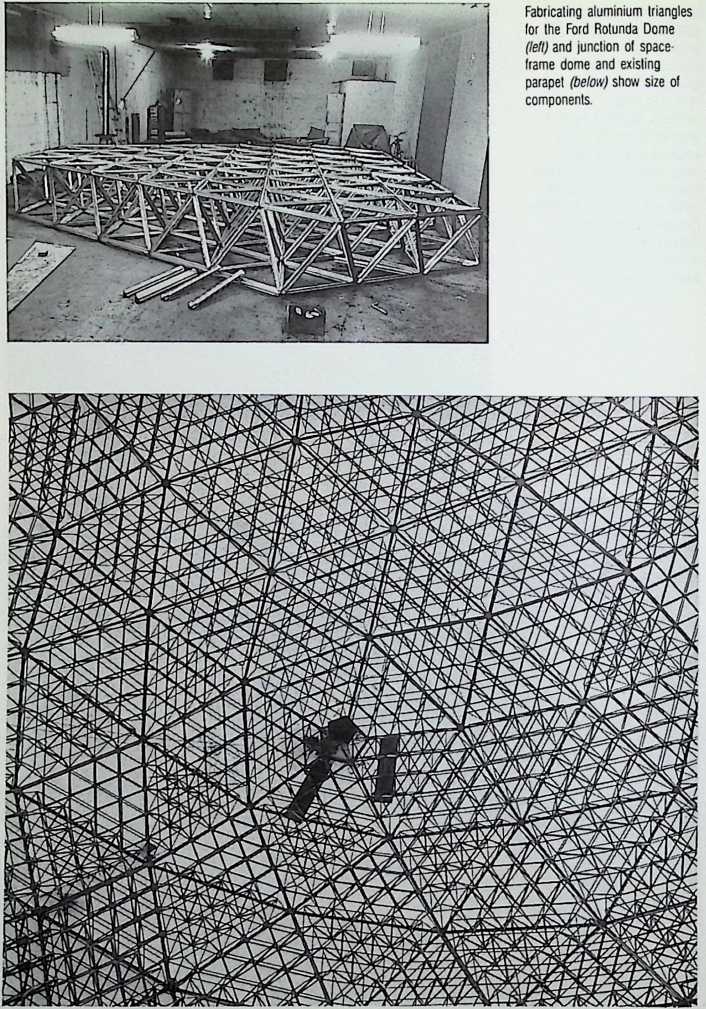

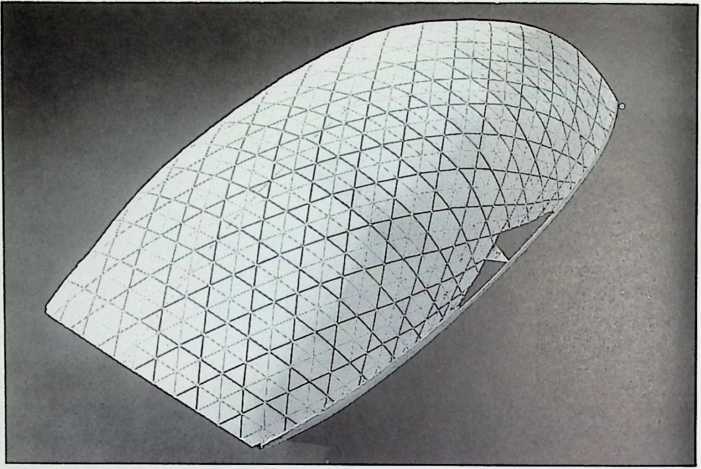

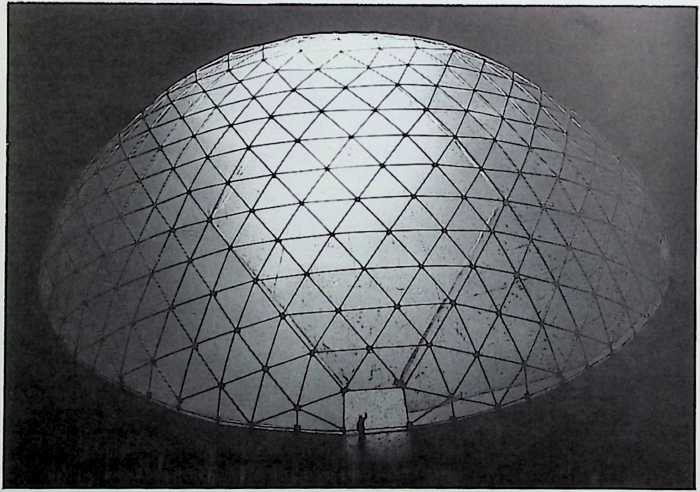

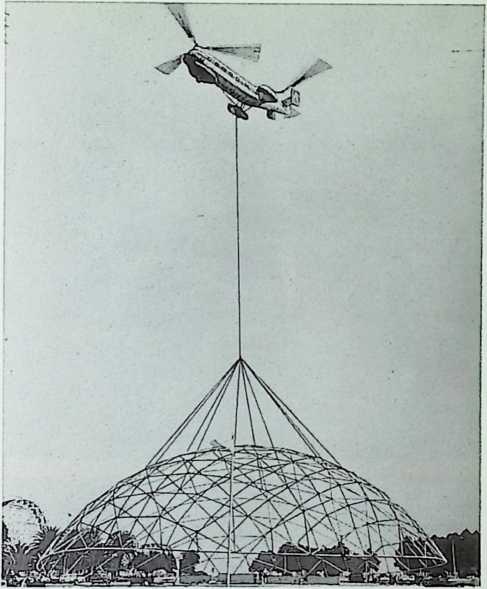

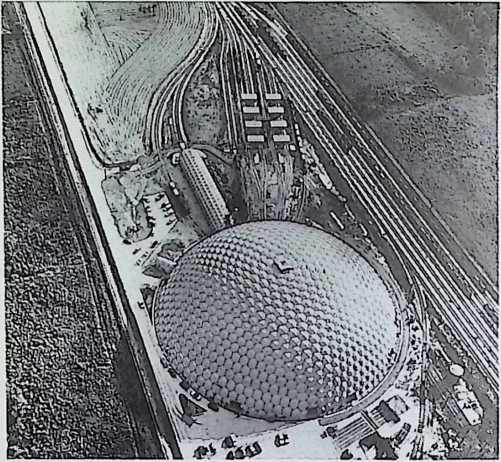

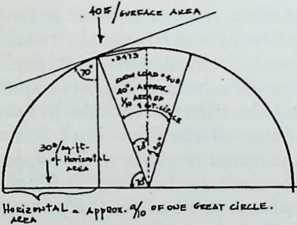

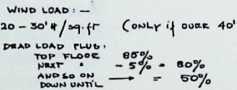

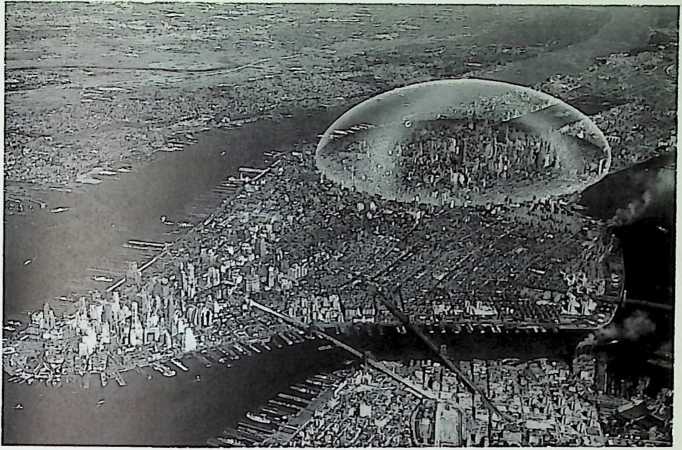

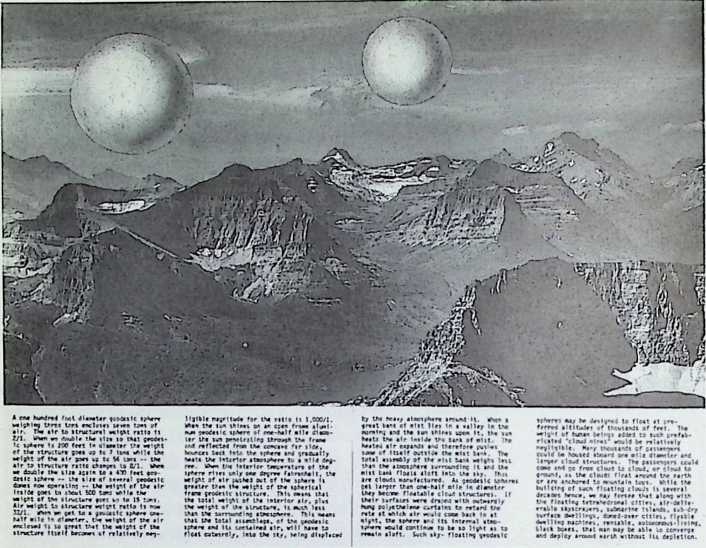

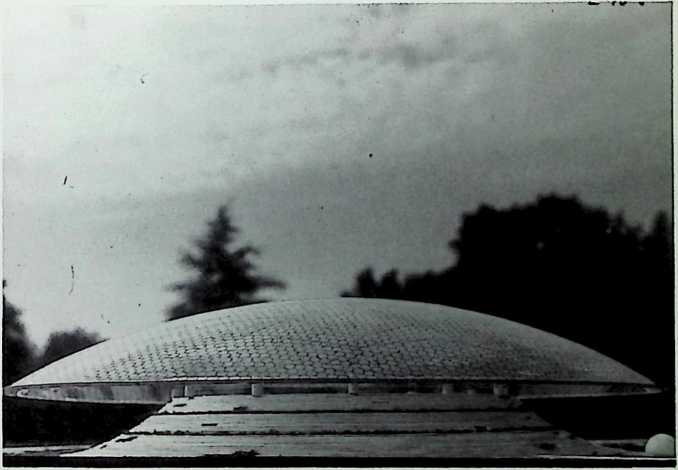

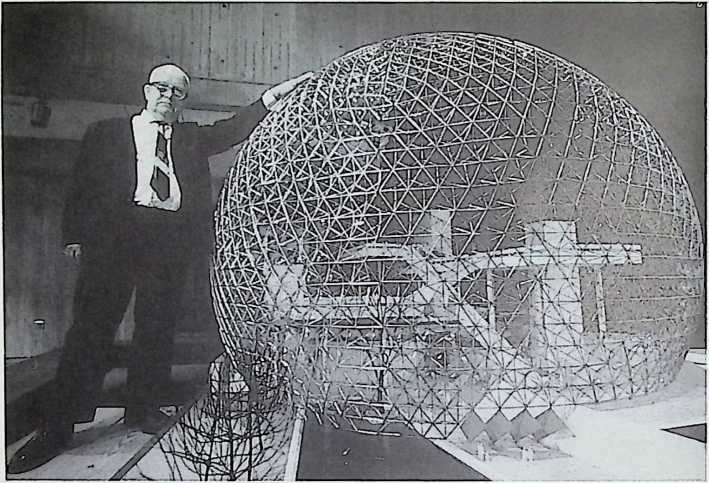

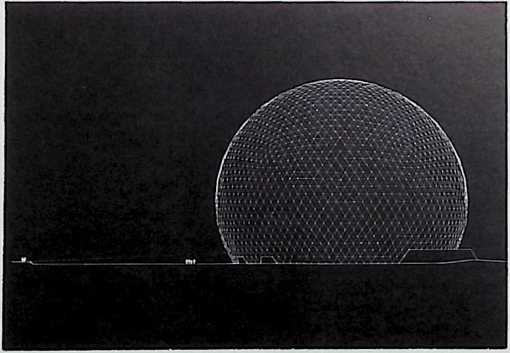

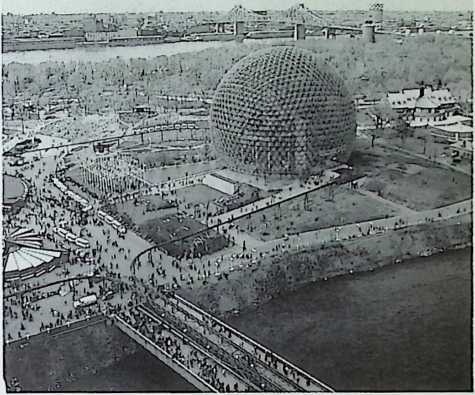

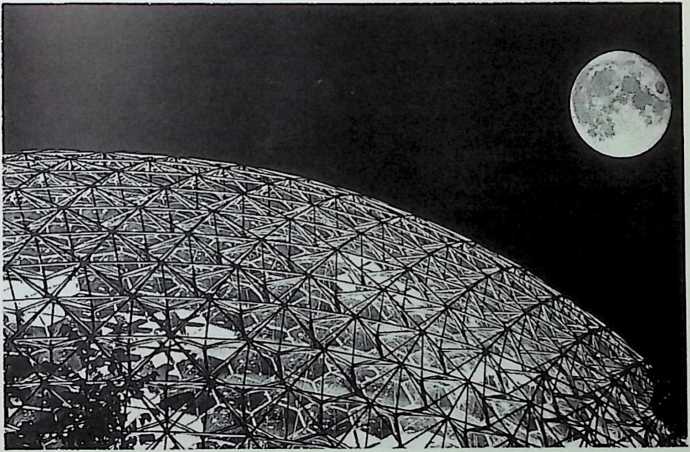

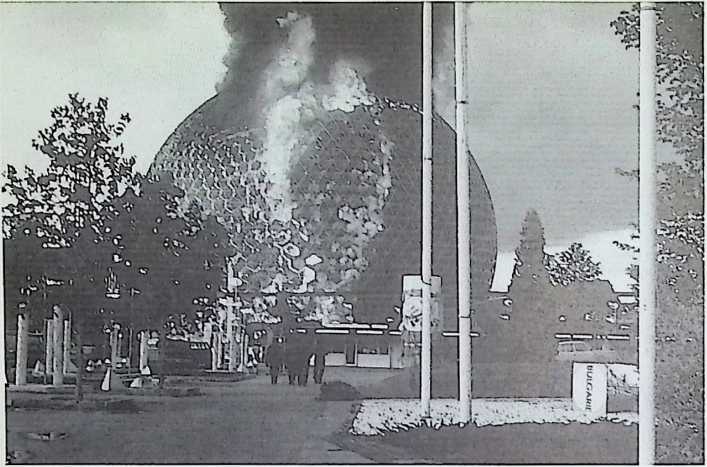

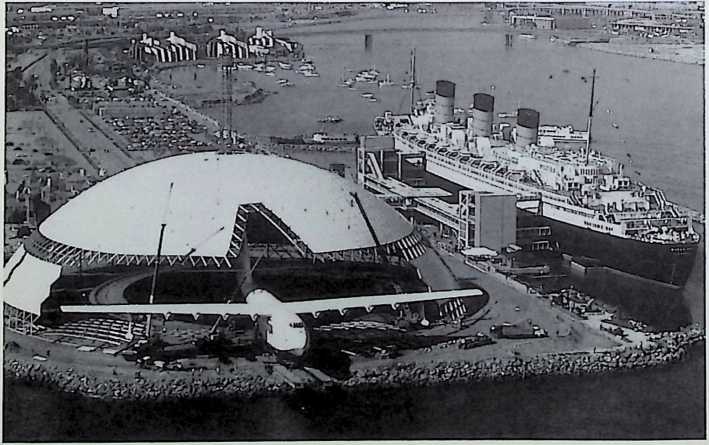

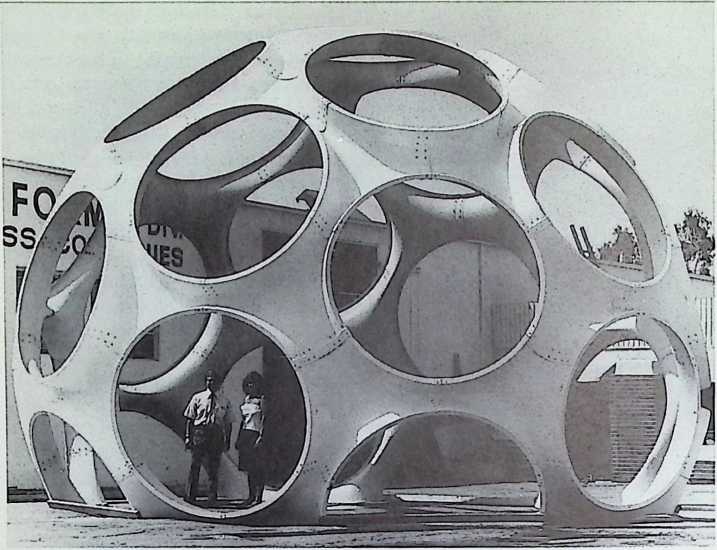

Fuller’s only great commercial success, and his best known invention was the geodesic dome, a triangulated space-enclosing technology that was domical in shape in order to enclose the maximum internal volume with the minimum structure. Patented in 1954 no less than 300,000 Geodesic Domes were built over the next 30 years, for purposes ranging from sports arenas to subtropical housing and the construction of a permanent American base at the South Pole. Projected dome structures included mile-diameter flying spheres and floating cities. The last in a long line of Fuller’s dome refinements, the revolutionary ‘Fly’s eye dome’ also intended as a cheap dwelling enclosure, was still under development two years before his death.

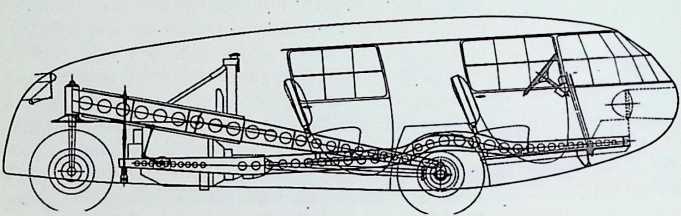

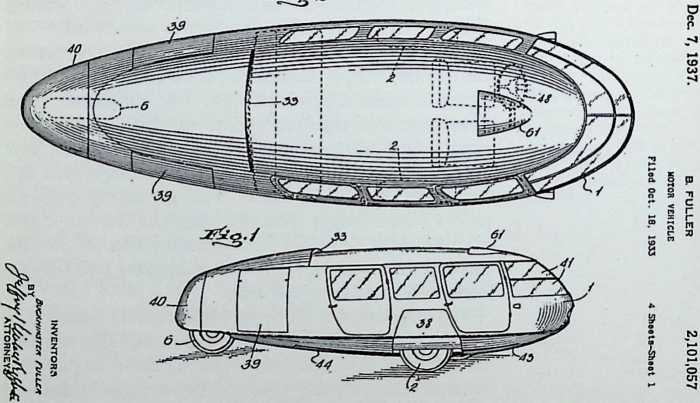

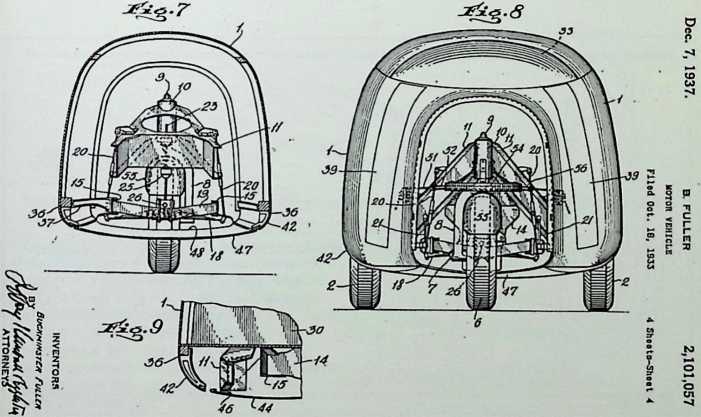

But despite this last great victory, for most of his life Fuller remained not only outside the mainstream of American industrial production, but outside the mainstream of accepted design culture. His revolutionary ‘Dymaxion Car’unique in being rear engined but front-wheel driven, and intended to speed along roads like a taxiing aeroplanewas toyed with by the United States motor industry for more than a decade, but its ideas were never taken up in the form in which he introduced them. His even earlier predictions of the feasibility of ‘jet-stilt’ air-cushion vehicles,played no part in the subsequent development of the helicopter or the hovercraft.

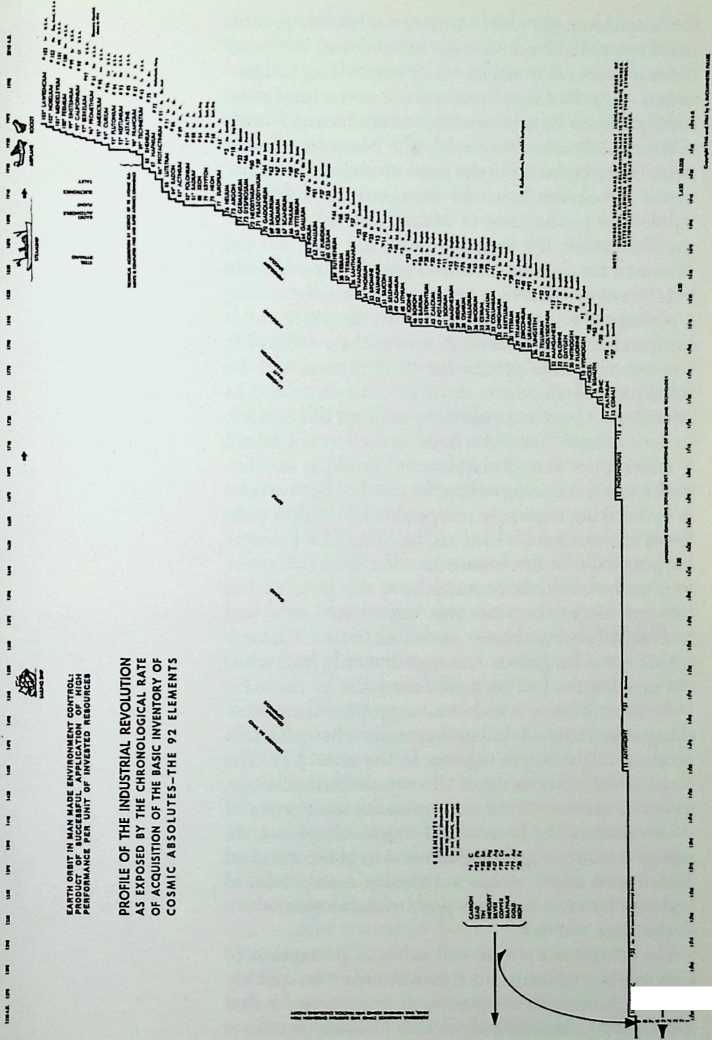

As well as being a futuristic and prophetic designer, Buckminster Fuller was author, co-author, or a major contributor to over 50 books, and the subject of thousands of newspaper articles and interviews. In all of them he proselytized tirelessly for the creation of a world design science to avert ecological catastrophe and promote resource conservation, notions that were a generation ahead of their time.

Today, less than a decade after his death, Fuller’s reputation is poised uneasily between oblivion and cult status. It fits somewhere between the heaped honours of an architectural profession that has already largely forgotten him, and a growing environmentalist opposition to all uncontrolled industrial production. This balance is so delicate that, while ecologists and environmentalists in their new Green political prominence could do no better than to seek a framework for their ideas in the collected works of Buckminster Fuller; the withdrawing forces of industry toounder attack from every quarter for exhausting resources and polluting the environmentwould also find a ‘blueprint for survival’ in those same pages of ideas and inventions.

For the master of ‘more for less’, if he were still alive, there might be something gratifying in this pregnant symmetry.

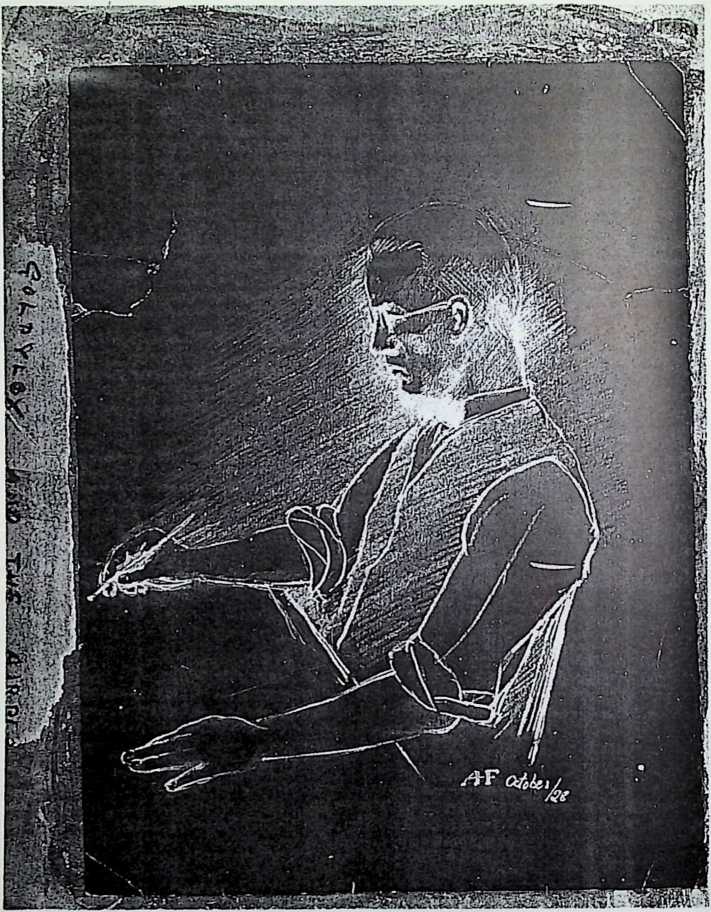

Goldylox and the Airplane1: a portrait of Fuller drawn by his wife Anne Hewlett Fuller in 192a

¶ brief encounters

I asked myself, (1) Can you trust yourself never to turn to your own exclusive advantage the insights entrusted to you only by the realization of benefits for all humanity and the Universe itself? (2) Can you also be sure that you will never exploit your insight by publicly declaring yourself to be a special son of God’ or a divinely ordained mystic leader? (3) Can you trust yourself to remember that you qualified for this functioning only because you were an out and out throwaway? (4) Can you trust yourself to reliably report these facts to others when they applaud you for the success of the experiment with which you were entrusted?

Fortunately, I can, may, and do report to you that I have never broken that trust nor have I ever been tempted to do so.’

Richard Buckminster Fuller 1983

Over the years of his life, thousands of writers and journalists interviewed Buckminster Fuller. There is no record of all the interviews he gave. A ‘Basic Biography’ published by the Buckminster Fuller Institute in March 1983 reproduced the titles contained in the cuttings file of the New York Times from 1922 to 1982, and revealed 520 items. Assuming that only one quarter of them involved interviews of one kind or another, and taking into account perhaps another 50 major newspapers and magazines world wide, we can see that Richard Buckminster Fuller might have been interviewed 5,000 times.

Among the last of these countless interviews was one carried out by Fuller’s admirer Dr Anwar Dil, the co-writer of the book Humans in Universe published in the year of Fuller’s death. As a document Dil’s interview is long and predictable for the most part, but suddenly, in the midst of an exhaustive discussion of what the sage’s final message to the parents and children of the world should be, Fuller saysand in the light of the statistics given above we can be sure that he is telling the truth‘Everything I have said to you, I have written or said before.’

‘Would you at this point make a statement that you have not written before? What would that be?’ Says Dil.

Fuller thinks. Then he replies; ‘One of the things that interests me is something strange that occurs on every occasion of my making a scientific and socially advantageous discovery and a special-case technological invention therefrom, in general support of my attempting to solve human problems with technology.’

‘Whatever the discovery and invention may be, I have always had the experience of some enchanting female coming into my life concurrently with the scientific discovery. You, Anwar, have brought my darling wife into our discussion, despite flirtations and sex with others, I have never stopped loving my wife above all others. What I am getting at here is the Iliad and the Odyssey or Aeneid like sirens or other females’ interceptions of the explorer’s route. This has repeated itself a number of times in my life. Every time I am about to make a discovery and I am developing a high sensitivity of thinking, along comes a, to me, exceptionally charming female with whom I find myself tending to fall in love. Only when I have successfully restrained myself from falling further and have applied myself exclusively to the discovery or inventing, and only then, do the critically relevant conceptions occur which secure my comprehension of the significance of the discovering and/or inventing and what my responsibilities are in making the discovery and inventions effectively available to humanity.’

‘At any rate, that is something I have never written before. I suspect it may be importantly true.’ Unlike Anwar Dil, I only ever had one face to face encounter with Richard Buckminster Fuller. It took place thirteen years before the occasion on which I last heard him lecture, ten days before his death, when he spoke at the Royal Institute of British Architects in London on the occasion of the award of the Royal Gold Medal for Architecture to his former collaborator and friend Norman Foster. Foster was, at that time, designing a complex double geodesic home for Fuller that was to have been erected on a site in Los Angeles. On the earlier occasion thirteen years before, I had been sent to interview Buckminster Fuller for one of the first issues of the magazine Building Design. Prior to that encounter I had only an abstract impression of him, formed by seeing his name and his projects, chiefly domes, in books and magazines. The idea of his role and personality that I had gathered was negative. Fuller, I believed, was a kind of mathematical huckster, in some suspicious way connected with American foreign policy. He was, I thought, a dangerous technocrat, trying to remove the subjective, creative element from architecture and replace it by universally applicable geometrical formulae. Notorious for lecturing student audiences for four and five hours at a time, Fuller seemed to me to be a heartless, totalitarian figure, crucially lacking in human values.

Years before the interview that was to transform my perception of the man, I had put this unfounded prejudice in writing. In the early 1960s I was a member of a dissident student group at the Oxford School of Architecture called the ‘Progressive Architecture Movement’ which had leafleted the audience at a British Architectural Student Association (BASA) conference addressed by Fuller. The leaflets, which I had composed, bore (to my eternal shame) a suitably modified picture of the sage’s head with the slogan; ‘Come off it BASA! Buckminster Fuller’s head is a geodesic dome. Inside it is a copy of the Reader’s Digest ’.

So grandly are the paradoxes of life arranged that twenty years later it was an excellent article about Buckminster Fuller by Emily and Per Ola d’Aulaire in that very magazine that confirmed my desire to study the story of his life and write this book.

On February 28th 1970, the day that I interviewed him, Richard Buckminster Fuller, then aged 75, was staying at the Stafford Hotel in St James’ Place, London, a quiet cul de sac near Piccadilly. With him during the interview was Shoji Sadao, his longtime Japanese collaborator who is today curator of the Isamu Noguchi gallery in New York. Fuller and Sadao were in England to discuss the proposed, but later abandoned, Samuel Beckett Theatre in Oxford. This project was to have been carried out in association with an admirer of his, that same later RIBA Gold Medallist, the architect Norman Foster.

My plan for the interview was simple. Filled with the overweening confidence and scepticism of youth I was determined to show Richard Buckminster Fuller and the readers of Building Design that I for one would not be put off by two hours of autopilot geometrical and algebraic nonsense about the universe like all the other Fuller groupies. I wanted to make Buckminster Fuller talk about the housing problem (a subject I believed that I knew something about) and not about domes or icosahedrons. The next two hours were not a success from the standpoint of this plan.

For a start Fuller was late for our two o’clock appointment. I and the staff photographer had to watch horse racing in the television lounge for ten minutes before he and Sadao arrived at the hotel and led me up to his small room on the fifth floor. Once there Fuller ordered a fruit salad and a pot of tea from room service and we all sat down. At 75 he was stiff of movement and clearly hard of hearing, but his energy was surprisingas when he sprang up to open doors, pulled up chairs and indulged in elaborate mimicry to make a point. I later learned that he had been taught these athletic movements, as well as his extravagant lecturing mannerisms, by his daughter, the dancer Allegra Buckminster Fuller.

After the photographer had left, I moved in with my first question. It was a killer. ‘Mr Buckminster Fuller, forty-three years ago you announced that a world housing industry using advanced technology was inevitable, yet every one of your efforts to bring such an industry into existence, before, during and after the Second World War has been a total failure. Why do you suppose that is?’

Fuller’s astronaut-stubbled head stared at me with what looked like unseeing eyes through pebble glasses whose frames incorporated stereo hearing aids. His whole body, reshaped by his stiff suit, collar and tie as are those of most thin old men, was immobile, his brain working like a computer sorting something out. ‘I would contradict that completely’, he replied evenly. ‘In the first place because no world housing service industry can ever be based on products that people can buy. It is a whole process. If people had to go to a market to buy all their own guts, with them hanging up all around, nobody would buy them at all. There’s not any part of a human being that anyone would buy if they did not already have it anyway’.

I felt myself losing the initiative. This reply was tangential but not perhaps totally irrelevant. I temporized.

‘What about brains. Wouldn’t they buy brains?’ ‘What those awful things!’ Fuller laughed. He had figured me out. ‘OK, so that’s where you start’.

From then on he went on to explain what he meant by a process instead of a product, using the story of how the telephone system had been successful precisely because the instruments had never been sold, only rented. In the interests of recording a minor comment on the present state of the telephone industry it is worth noting that he predicted exactly what has happened now that telephones are sold. ‘If they ever sell telephones’, he said in 1970, ‘before long you will get a Christopher Wren telephone, a Louis XIV telephone, a World War One trench-type telephone, then an alligator telephone…All this horrible equipment you will pay a terrible price for and it will stop development of the service itself’. Then he resumed his narrative.

‘The lesson of the telephone taught me back in 1927 that housing was going to have to be a service industry, not a product industry. A truly logical complement to life embodying the principles of nature, recognizing entropy and the inevitability of change. A bird picking up twigs to make a nest turns the whole action into a complement of its life. A spider makes a web, a mole makes a tunnel. They alter their environment in preferred ways. Human beings do that too. They are not unusual in that, only the extent to which they do it’.

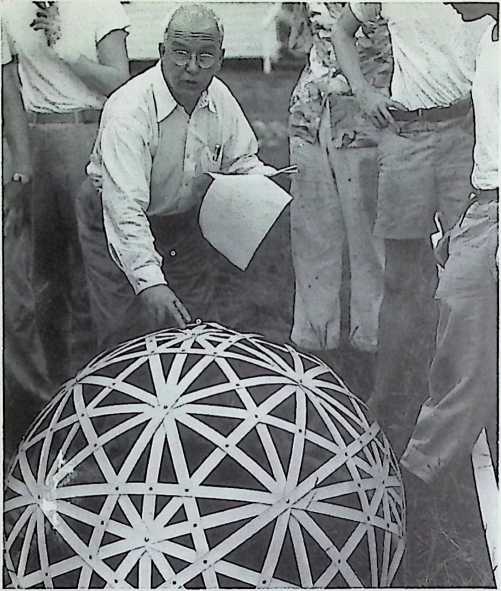

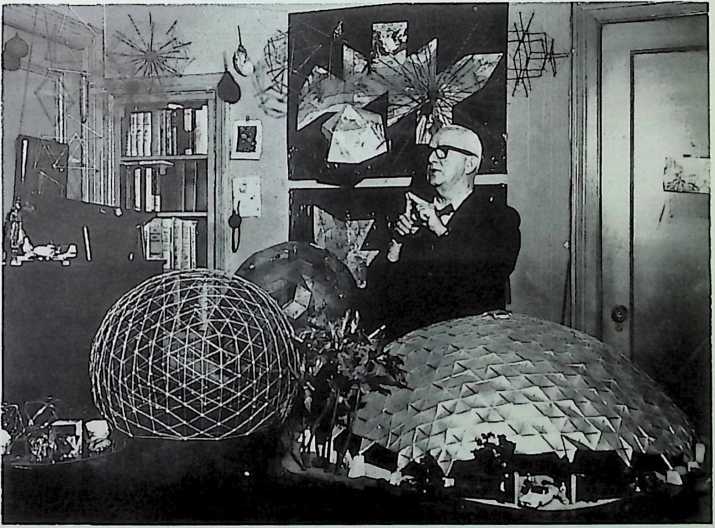

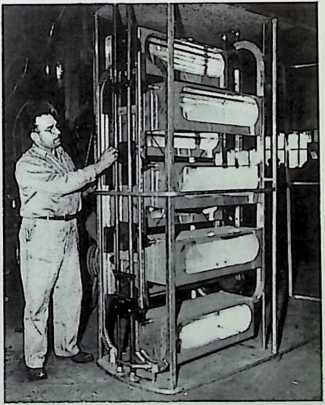

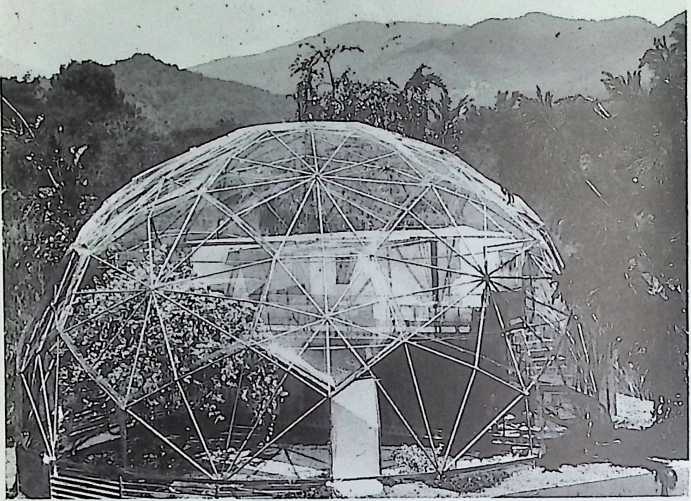

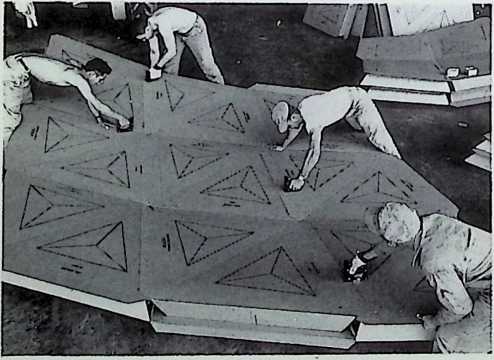

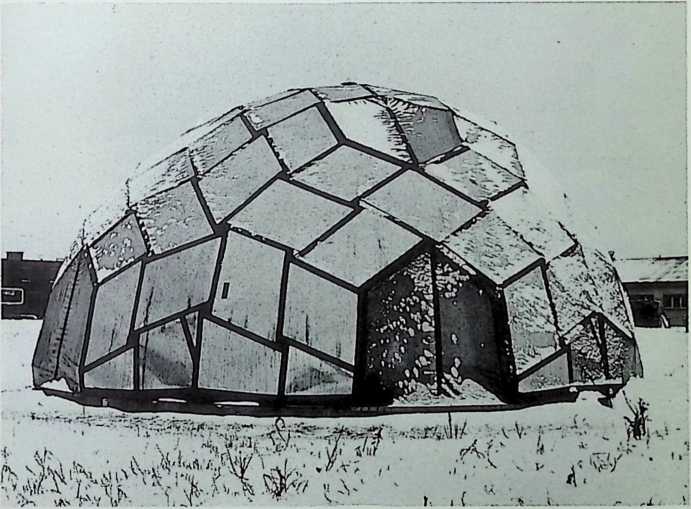

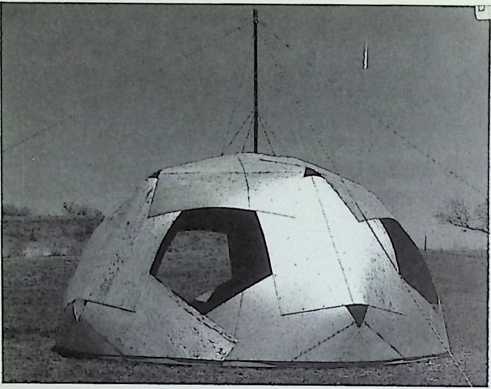

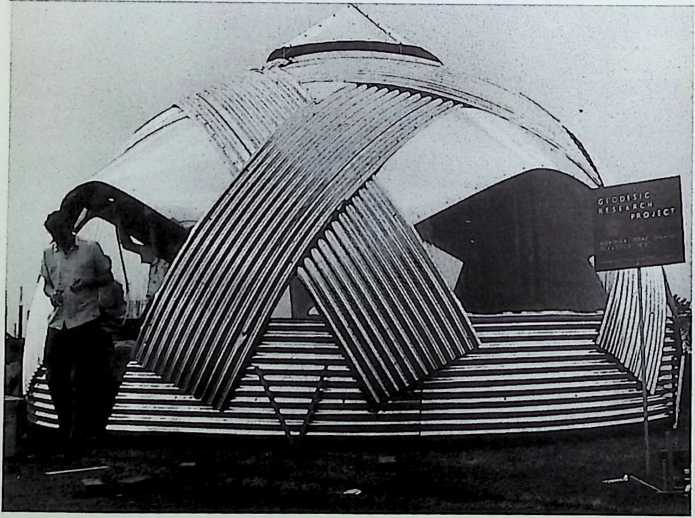

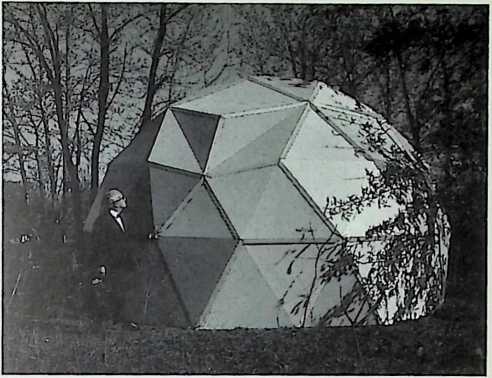

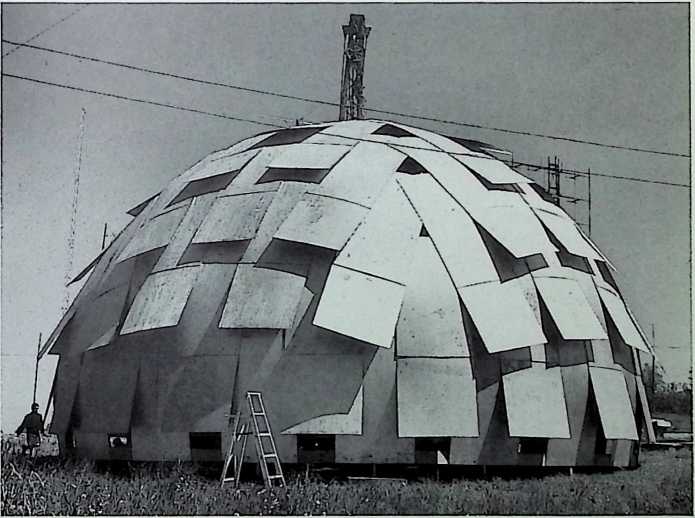

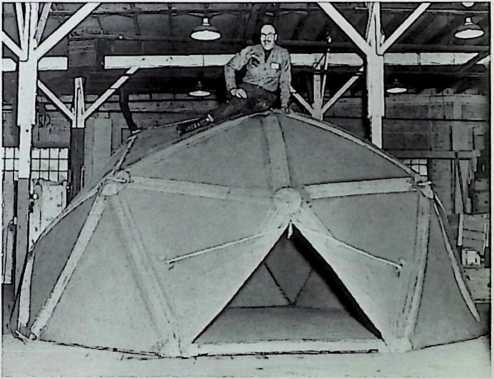

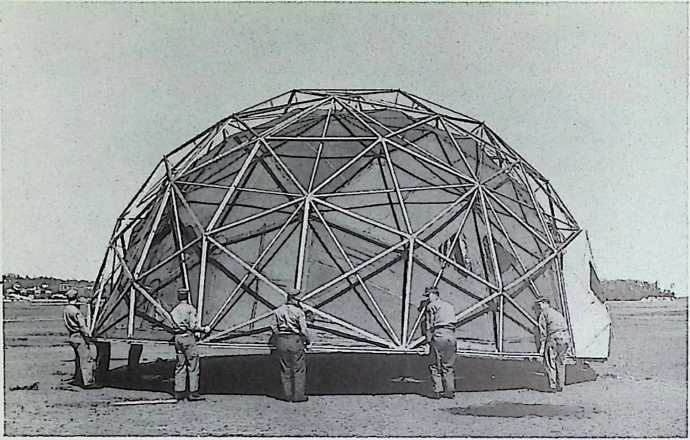

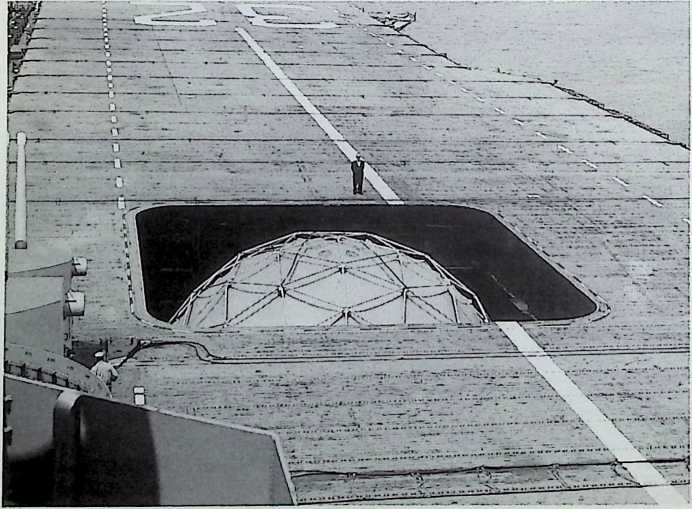

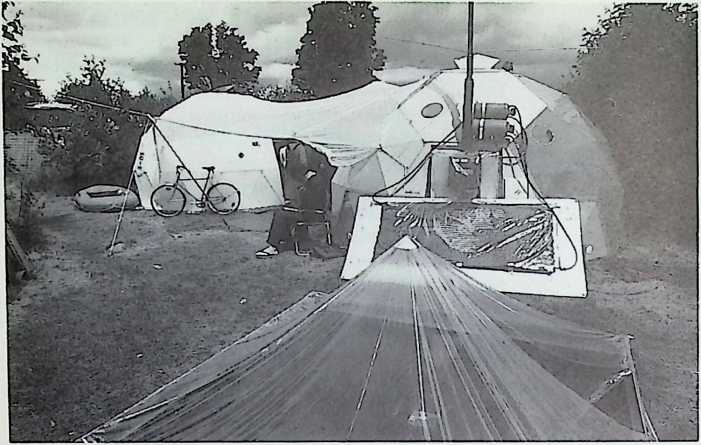

Notorious lor lecturing student audiences lor four and five hours at a time,’ Buckminster Fuller at Black Mountain College. North Carolina in 1948 with lhe prototype Venetian blind dome (left). Seven years later an audience ol English scientists who worked on lhe Cambridge DNA/RNA discoveries (below left) endures a Fuller lecture on synergy.

Notorious lor lecturing student audiences lor four and five hours at a time,’ Buckminster Fuller at Black Mountain College. North Carolina in 1948 with lhe prototype Venetian blind dome (left). Seven years later an audience ol English scientists who worked on lhe Cambridge DNA/RNA discoveries (below left) endures a Fuller lecture on synergy.

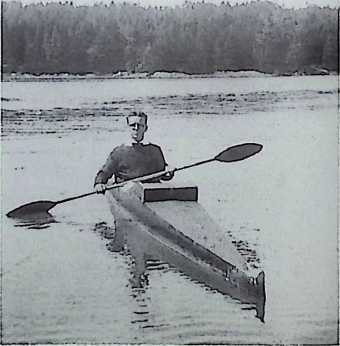

Fuller the explorer (below) in a kayak oil his familys ■ later his own • summer home on Bear Island, Maine in 1911; Fuller the sailor (right), at the wheel of the family boat Wego, volunteered for United States Navy patrol duly at the entry of America into the Great War. Fuller the talker (below right) holding forth in New York in 1947.

Fuller the explorer (below) in a kayak oil his familys ■ later his own • summer home on Bear Island, Maine in 1911; Fuller the sailor (right), at the wheel of the family boat Wego, volunteered for United States Navy patrol duly at the entry of America into the Great War. Fuller the talker (below right) holding forth in New York in 1947.

‘I say that housing has to be a service. It should be. When you use your house and think about it as we do today, as a castle full of treasure, to say; ‘You’re supposed to die! You stay outside my walls! He rose suddenly to his feet with a menacing gesture‘I can roar like a lion! and then sat down again and lapsed into a short, ruminative silence. Then he looked up. ‘By this time you are supposed to be scared to death. Housing as an advertisement for how great you are is not what I am talking about at all’.

‘Yes, but housing policy…’ I interjected. Fuller waved his hand, he was coming to that.

‘Now I said earlier that I would contradict you completely and I will. After the First World War I was horrified by the progress of the automobile industry in America. There were 125 car companies in 1919, but between then and 1926 they were reduced to eight companies. It was the most immoral thing I ever saw, all those automobile companies going bust, and yet it was the most successful period in automobile developmentthe price of Ford cars dropped by 30 per cent. That such a success should have been accompanied by bankruptcy after bankruptcy seemed to me to mean that our society just didn’t understand proper accounting. I looked into it and found that the accounting system we were using was invented solely for agriculture. That was because it was the main business of man for centuries’.

‘Now crops are an annual thing. Either they come in or they don’t. So you get annual accounting in agriculture because it makes sense. But I realized that the gestation rates of industrial undertakings were not annual like agriculture, even though everybody was investing in them as though they were. If a productive industry had a bad year, all its stocks went down and so on. I saw that we were not thinking in the right bracket and I understood that that had accounted for the bankruptcies. It was then that I started trying to work out the real gestation rates for different industries taking this basic failure into account. Would it be a thousand years before man’s productive thinking could be catalyzed in a better way? In which case nothing I could do would have much effect at all. Or would the timescale be much shorter?’

‘Well, by cataloguing all the known inventions and scientific events, logging the rate at which scrap metal came back on the market as a raw material, I found that in electronicsthen a very new industry, an invisible world in which you couldn’t see the waves and they were handled mathematically so that you could prove them mathematically without too much argumentthings happened quite fast. The gestation lag between invention and use in electronics was about two years. I found in the airplane industry there was a five year lag. In the automobile industry the lag was ten years. Railroading about fifteen years. Skyscraper building, a much different technology from housing, had about a twenty-five year lag. In the housebuilding business the lag was between forty and fifty years’.

‘Much as I was interested in developing a new housing concept as a young man, I knew then that I had to count on half a century between intention and industrial production. If I wasn’t ready to wait forty or fifty years…Don’t tackle it. I knew in 1927, 1928 that anything I did during those fifty years would be premature for production, and I was right. But since that time everything has been coming in on schedule and the industrialized dwelling will be coming in too, right on the nose, between 1972 and 1975, and the new industrialized houses will look an awful lot like the Dymaxion House too’.

This was an impressive theory, but I was still prepared to stick to my guns. ‘Surely’, I ventured, ‘there is less sign of an industrialized housing industry now than there was twenty years ago. Today we have a crisis in housing…’

‘If we have a crisis in housing it is because old style housing is just about stopping’, he replied quickly. ‘It is in the United States anyway. In 1927 I wrote a book pointing out how the government was getting involved in housing because private industry had dropped itnot just because it was unprofitable, but because it was completely obsolete. Since that time our government and yours have got involved deeper and deeper. In the United States they have had to take over all the mortgages. We have been underwriting obsolescence for forty years. We have been trying to revive a dead man! We have got a corpse on our hands and it’s taken nearly fifty years for anyone to realize that it’s dead!’

Buckminster Fuller paused dramatically. His voice in the small room had risen to a boom not far short of lecturing strength. His fruit salad was unfinished, his tea undrunk, and mine too. Whenever I interjected, he seemed to get more angry: but if I did not interrupt him there was no telling where all this might lead.

“But I’m concerned about all the political changes…” I tried again.

“And I’m concerned that you started off by calling me a failure’ he thundered back. ‘Failure is a word invented by men, there is no such thing as a failure in nature. Man’s confidence in his judgement has failed, nature never fails. Don’t talk to me about failure, it’s a word like pollution invented by ignorant men. There is no such thing as pollution. Nature invented beautiful chemistry and men have pulled out some here and left in some there…All we do when we pollute is make recovery and recycling difficult by spraying the waste products from one process into the air or the sea where it’s difficult to get them back again, that’s all. All the young people are going wild today because they know the old people have been asleep at the switch! The whole housing mess we’re in comes from the ignorance and fear of financiers. The governments of the world have had fifty years to prepare for a HOUSING SERVICE INDUSTRY and they have done nothing at all!’’

A thunderous silence fell across the room. Sadao sat silent at a small table. I sat in my chair. Fuller was standing, striding, limping slightly about the pathetically little space left in the hotel room.

‘But don’t we lose something important if we lose the idea of possession and ownership,’ I tried finally, ‘These things are ancient traditions…’

‘You never did own a thing so you can’t lose a thing’, he growled in reply. ‘You’re losing a stupid notion that’s all. You don’t own anything or anybody. You don’t have to own the ocean to have a boat. You don’t have to own the sky to have an airplane. You won’t have to own anything to have a really good dwelling service around our universe. My revolution is to make the old thing obsolete, not to attack it. The old method of housing will soon be too expensive, too slow, too cumbersome. Land ownership will go the same way, it will become a liability. These things are already happening. In the United States people buy house with loans every forty years and then leave town every four years. They buy cars over three years, and then trade them in as soon as they own them. Ownership is already out of date. Ownership is absolutely fallacious’.

Transcribing these words twenty years later, I can still feel their force, but now I can understand it better. I had thought myself daring to call Buckminster Fuller a failure, but in fact my performance had been a flea bite alongside the travelling hornet’s nest of detractors of.whom I knew nothing who had been saying the same of him for twice as long as I had been alive.

In later years, when I learned more of his life, I think I came to understand what being called a failure must have meant for him. Richard Buckminster Fuller had suffered mocking, cowardly, inadequate commentators stretching back before the day I was born to the very physical failure that would have pre-empted all failures for any lesser man. For he was a small and inadequate child born to a proud New England family that traced its ancestry back eighteen generations to Thomas Fuller of London, born in 1420.

When he grew to manhood Richard Buckminster Fuller was only five foot two inches tall, his head was unnaturally large and his left leg more than an inch shorter than his right, giving him a gait ‘like a penguin’.

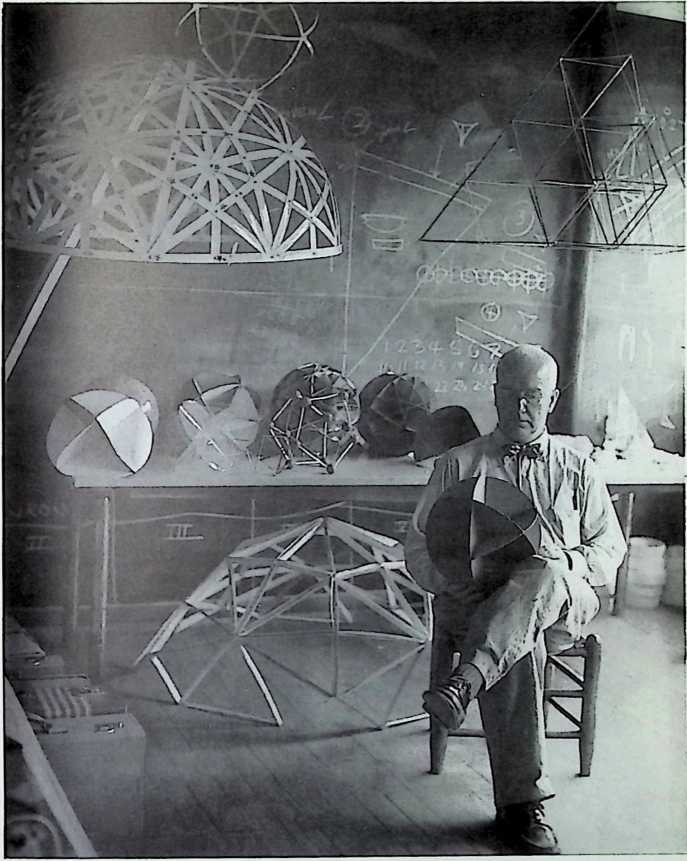

Other portraits: Fuller the lone genius (left) in a Greenwich Village studio in 1929 with a frame model of his -D mast-supported house; Fuller the ambassador (right) guiding HRH Princess Margaret and Lord Snowdon around a 1962 exhibition of his work at the United Slates Embassy, London; Fuller the philosopher (below) in 1967 surrounded by geodesic models in his study al the University of Southern Illinois.

As a child he was cross-eyed, unpopular, badly behaved and bullied at school. He was sent down from Harvard, where every male Fuller since 1760 had graduated. He was bankrupted in business, where his father had been a model of probity. He was fired from jobs and ridiculed by his peers in engineering, architecture and construction. In 1927 he was sacked from his post as president of ‘Stockade Building Systems’ after five years. In the same year he was shattered when his three year-old invalid daughter died in his arms and her last words were; ‘Did you get me the cane, Daddy?’a reference to the walking cane he had promised to buy her when he had left the house to go to a collegiate football gameand had unfortunately forgotten.

One year later he offered the patent rights in his revolutionary ‘4-D’ house to the council of the American Institute of Architects, whose then vice-president was his father-in-law, and the Institute not only rejected the gift but caused the gratuitous insult; ‘Be it resolved that the American Institute of Architects establishes itself on record as inherently opposed to any such peas-in-a-pod-like reproducible designs’, to be read into the minutes of the meeting held to discuss the matter.

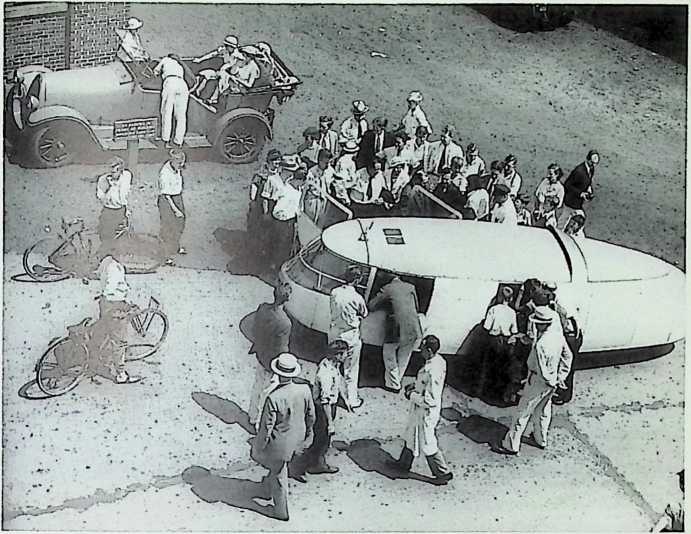

At least twice Buckminster Fuller’s failures were so notorious as to lead to his being pilloried by the press: in 1934 when an accident with his revolutionary Dymaxion car resulted in an outcry over the death of the driver; and again in 1946 when his prefabricated housing company ‘Fuller Houses Inc’for which thousands of dollars worth of stock had been sold on production targets of 20,000 units a year, and upon which the job prospects of 20,000 wartime aircraft workers depended was liquidated through his own stubbornness.

The Richard Buckminster Fuller of that day in the Stafford Hotel knew what failure was, he had been called a failure by experts. In fact, although I did not know it, his success, his reputation, his immortality rested upon a structure of failures so vast and ambitious that only a man of superhuman courage and determination could have supported it.

This much I did not realize at the time, but I did understand that the end of my interview with Richard Buckminster Fuller had arrived. I had asked only one of the ten questions I had prepared, but the emotional intensity in the hotel room was too powerful for me to speak, and for Fuller, further elaboration of what he had already said would clearly have been superfluous.

As I put my tape recorder and notebook away and put on my coat. Buckminster Fuller addressed me in a different tone that showed that his anger had either been simulated, or had quickly abated. ‘I hit you hard that time because I want you to remember what I said. I’m an old man and I won’t be around forever’.

I shook hands with Fuller and with Sadao, who had said nothing throughout the interview, and I left the hotel. I went back to my flat in Paddington and began to transcribe the key parts of the tape. The published version was necessarily incomplete, but the essence of the encounter was there. The only important omission was Fuller’s message to me as I left.

As an interview subject, especially towards the end of his life, Fuller was for the most part, as he confessed to Dil eleven years later, ‘saying all the things that he had said or written before’. And today I know that the verbal counter attack, the practiced rage, and the final gruff conciliation that he employed to such effect on melike the theatrical gestures taught him by his daughter had all been used before.

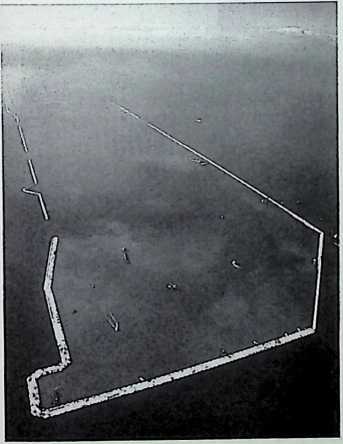

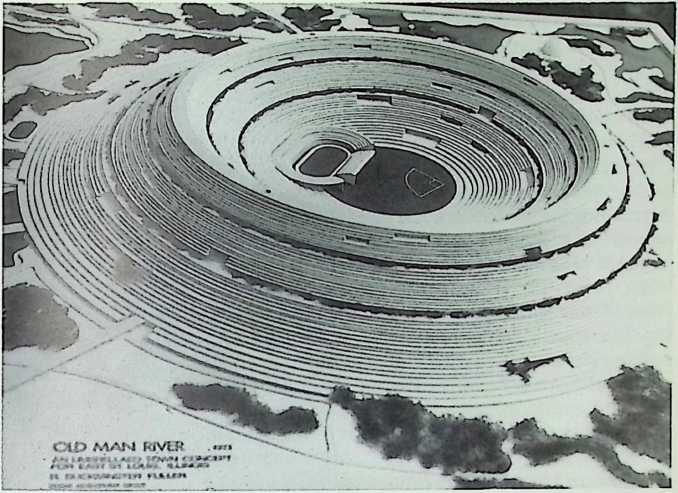

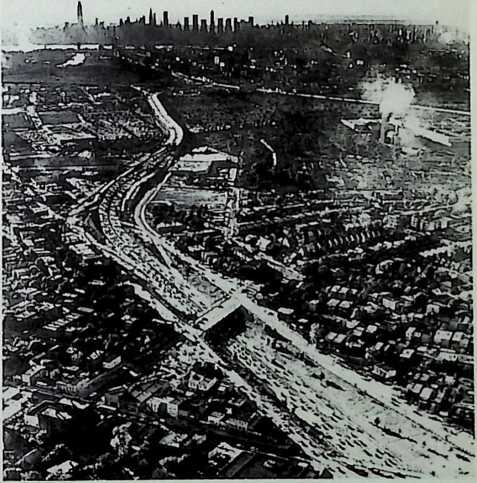

The significance of his remark to Dil about women is less clear, it might be completely innocent, or it might represent a chink in the armour of a private man who would normally only speak of his private life as a historical thing. There were women whose names occur in the long story of Buckminster Fuller’s career; Romany Marie, who kept the bar he frequented in New York City in the 1930s; Cynthia Lacey, generally described as his personal assistant, whose face makes an enigmatic appearance in most of the magazine stories about the Wichita House; Katherine Dunham, the black dancer who played such an important part in raising community support for the Saint Louis ‘Old Man River’ project. But outside his family and his associates little or nothing is known about them or their relationship with Richard Buckminster Fuller.

In the beginning, as at the end of his adult life, there was only really Anne Hewlett Fuller, his wife. The permanence and unknowableness of their relationship is attested in a million ways, but one of them is accessible. In the Buckminster Fuller archive in Los Angeles there is a scraperboard drawing of the polymath, seated with pen in hand at a desk. On the back of it is an inscription that reads; ‘Buckminster Fuller by Anne Hewlett Fuller, his wife, sketched in their Belmont Harbour, Chicago apartment in 1928 as he completed the manuscript of ‘4-D’, and the invention of the Dymaxion House, as an objectification of his philosophy of industrialization’. On the front, in the margin is written enigmatically; ‘GOLDYLOX AND THE AIRPLANE’.

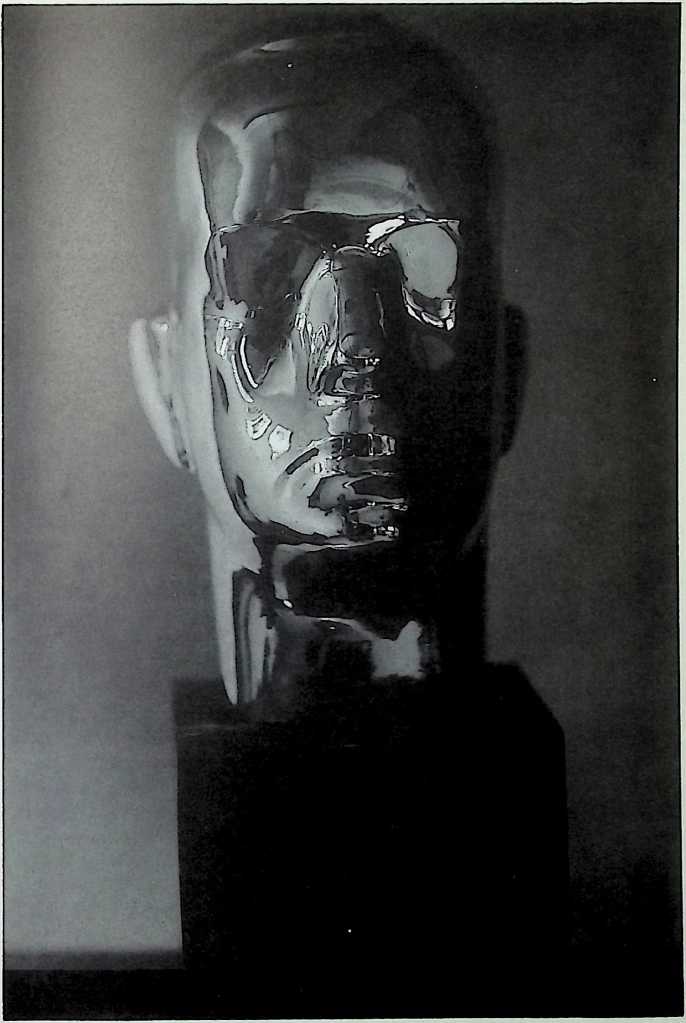

Fuller the immortal, alongside a bust of himself cast by his friend the sculptor Isamu Noguchi.

¶ the year of silence

“Picture on the shores a city of 4-D design, in place of the hit and miss, American Institute of Bow & Arrow Boys pile-em-up, paste-em-together architecture. This aesthetically interior-decorated architecture, or archaic style designing, is similar to our childhood toy shop boat-makers’ products, which enrage the senses of any child who knows boats…The aesthetic drivel with which architects, who are responsible for the styles, have been educated is partly responsible for this…”

Richard Buckminster Fuller 1928

Richard Buckminster Fuller never wrote or talked about his private life except, as his former associate Don Richter put it, ‘as a historical thing’. In a strangely depersonalised way he discussed the evolution of his own mind as though it were alone in the universe and still in the process of formation by events stretching back to the beginning of time. Fuller reminisced for interviewers and told his life story over and over again until it grew too long and involved to tell to anybody at one sitting, but it had only one truly personal episode. That episode was a catastrophe called ‘The silent year’ that came to an end at exactly the time Anne Hewlett Fuller, his wife, drew his portrait and wrote the words that we can all, almost understand.

Anne Hewlett was one of ten daughters of a New York architect named James Monroe Hewlett who had studied under Pierre Galant in the external ateliers of the Ecole des Beaux-Arts in Paris. During his life Hewlett became vice-president of the American Institute of Architects and designed the decorations for all the New York military parades at the end of the Great War. Born in 1896, Anne herself studied at the New York School of Applied Design from 1914 to 1915 and became engaged to Buckminster Fuller in July 1916. From then on she devoted her life to his support. They had two children, Alexandra, who was born five days after her parents marriage in 1917, and Allegra who was born ten years later at the beginning of the silent year. After 66 years of married life Anne Hewlett Fuller died in hospital in Los Angeles in July 1983 six weeks after major surgery for cancer. Her husband had collapsed and died in the same hospital at her bedside only 36 hours earlier.

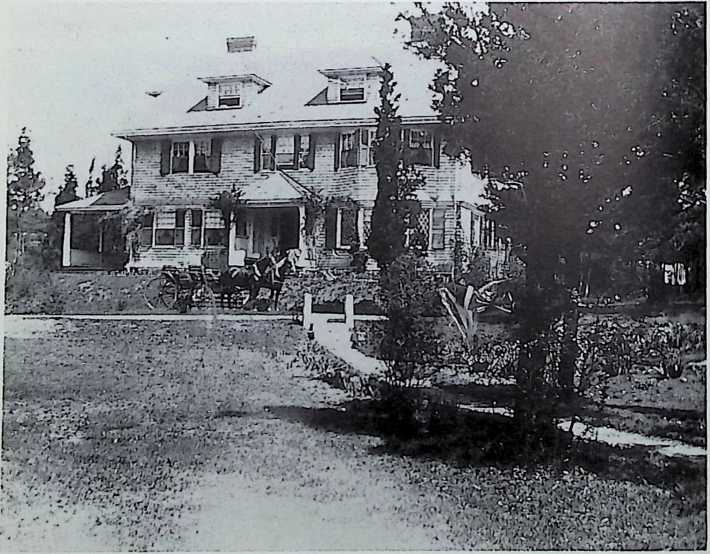

Richard Buckminster Fuller Jr. was born on the 7th of December 1895 in Milton, Massachusetts, in a house built by his father to the design of the architect son of Henry Wadsworth Longfellow the poet. He was the only son of Richard Buckminster Fuller, a leather and tea merchant with offices in Boston who died in 1910. His grandfather, Arthur Buckminster Fuller, was a hero. In 1862, during the American Civil War, despite his age and non-combatant status as chaplain to his regiment, he seized a rifle and volunteered to lead a charge across a bridge of boats at Fredericksburg, in the course of which he was shot dead. Arthur Buckminster Fuller’s sister, and Richard Buckminster Fuller’s grand aunt, was the feminist writer and personality Margaret Fuller, the author of Woman in the Nineteenth Century, who has herself been described as ‘the greatest woman of the 19th century’ by admiring modern feminists. Another grand-relative, James Monroe Sanderson, was the first manager of the Langham Hotel in Portland Place, London. Long before, Buckminster Fuller’s great, great, great grandfather, the Reverend Timothy Fuller (Harvard Class of 1760), was a Massachusetts delegate to the federal Constitutional Assembly that created the United States of America.

The house where Richard Buckminster Fuller was born in Milton, Massachusetts, now a suburb of Boston, The house was designed for Fullers father by the architect son of the poet Henry Wadsworth Longfellow.

At the time of his marriage the bearer of this intimidating lineage was an officer in the United States Navy serving in anti-submarine patrol boats off the New England coast. In his short life he had already been sent down twice from Harvard and packed off to Canada to work in a cotton mill. He had then worked in eighteen different branch houses of the Armour & Co meat packing company. In April 1917, at the age of 21, he had enlisted for the duration of the war and had prospered in the service, rising to be aide to Vice Admiral Albert Gleaves, commander of the cruiser and transport force of the United States Atlantic Fleet, charged with securing the supply lines to the American Expeditionary Force in France. In 1919 he was discharged with the rank of Lieutenant and rejoined the Armour Company in New York as assistant transport manager, in which post he remained for two years until he left to become sales manager to the Kelly-Springfield Trucking Company, which promptly went bankrupt. Fuller then returned to the Navy as a temporary reservist and was given command of the patrol boat Eagle. In the autumn of 1922 this short-term duty ended and he left the Navy for the last time. Very shortly afterwards his daughter died tragically of influenza.

The death of his four-year-old daughter in his own arms affected Fuller deeply. For months he remained unemployed, an unofficial pensioner of the Hewlett family. He developed an obsession with the role of old and damp housing in the influenza epidemic that continued to sweep the country. Eventually he went to work for his father in law as president of a company formed to promote the ‘Stockade Building System’, a method of building walls out of cement and compressed wood shavings.

Ambitiously Hewlett and Fuller opened five factories from New Jersey to Illinois for the manufacture of ‘Stockade’ blocks. As chief salesman Fuller spent long periods of time on the road and, according to his own account, developed into a heavy drinker. After three years he moved to Chicago in order to supervise the opening of another ‘Stockade’ factory in Joliet, Illinois, and in 1926 Anne joined him there. Throughout his time promoting the ‘Stockade Building System’ Fuller found himself opposed by sceptical architects, building control officers, contractors and competitors. Often his profit margin on a job was entirely erased by the need to put on full-scale fire tests of ‘Stockade blocks’ because officials would not accept the results of tests already carried out in other localities. The entire building establishment seemed to him to be one gigantic conspiracy in restraint of trade dedicated to preventing any improvement in the standard of construction.

Despite these difficulties Fuller continued to expand his operations until, early in 1927 Hewlett became pressed for money and sold his controlling shareholding in ‘Stockade’ to the Celotex Corporation. Fuller, as president, soon found himself in conflict with the new management. In the summer of 1927 he was forced to resign with little to show for his years of work. In August, before he had found a new job, his second daughter, Allegra, was born.

A wall of Stockade compressed wood shaving building blocks alter forty years.

The collapse of ‘Stockade’ marked one of the lowest points in Buckminster Fuller’s life. It marked the beginning of the silent year. Long afterwards Fuller would describe the way in which he tramped the shores of Lake Michigan in despair, intent on throwing himself in once he could convince himself that his life insurance policies would be of more value to his family than he was. In the end he failed to convince himself of this, experiencing instead what he called his ‘private vision’. ‘You do not have the right to eliminate yourself’, it advised him. ‘You do not belong to you. You belong to the universe.’ At the age of 32 he started out on a new life.

Moving from the expensive rented house he had occupied as president of ‘Stockade’, Fuller took his family to what he described as a slum, the apartment at Belmont Harbor where Anne was to draw his portrait. For the next year he refused to speak to anyone, even her. Instead he went into what can only be described as a creative breakdown, devouring books and legal pads, reading, writing and drawing with a compulsive and self-destructive energy.

Throughout this inner struggle he consumed books and magazine devoted to mathematics, science and architecture wherever he could find them. He conceived the idea of the Graf Zeppelin, the giant German dirigible, as ‘no more than a new kind of skyscraper laid upon its side’. He noted the German project by the brothers Rasch for mast-hung apartments diagonally braced to the ground like ship’s masts. Like the engineers of the small but influential ‘Technocracy’ movement he came to believe that the United States should be run as a machine, with its currency based on units of energy instead of money. Aided by a patchwork of such ideas, Fuller pitted his recollections of the advanced, and advancing, technology he had glimpsed in the Navy against the conventional Malthusian and Darwinian wisdom that seemed to endorse war, destruction and poverty by natural example. In the end he concluded that human inventive ingenuity could be pitted against the exhaustion of resources and the injustice of poverty to produce more by design than existed in nature. Thus mankind could succeed instead of failing. Adherence to the old economy of scarcity was in fact just another conspiracy in restraint of trade, this time by financiers and businessmen determined to make the new ‘more for less’ technology maximize profits instead of benefit humanity.

During the silent year he devised the title ‘4-D’ for the inventions that he scribbled down to reverse this negative balance. ‘4-D’ stood for ‘four-dimensional thinking’thinking in time instead of only in space, thinking of consequences for humanity instead of only immediate personal gain.

Emerging at length from his furious silence he resolved to promote the artifacts of this new thinking by setting aside any further idea of commercial gain and concentrating instead on the development of a ‘design science’ to obtain maximum human advantage from the minimum use of energy and materials. Almost his first practical step was to endeavour to patent the design of a ‘4-D’ mass-production house.

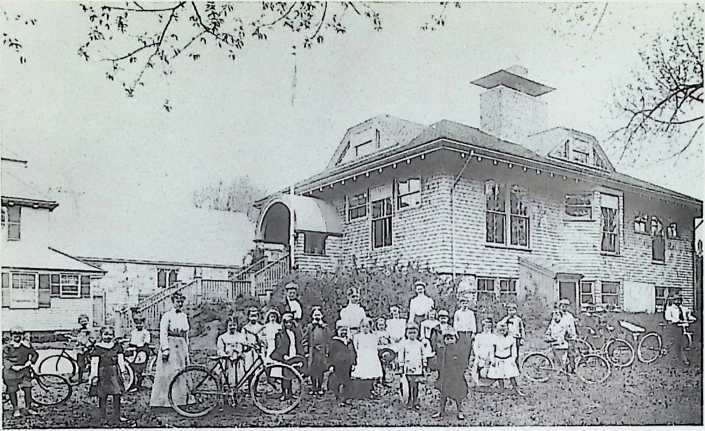

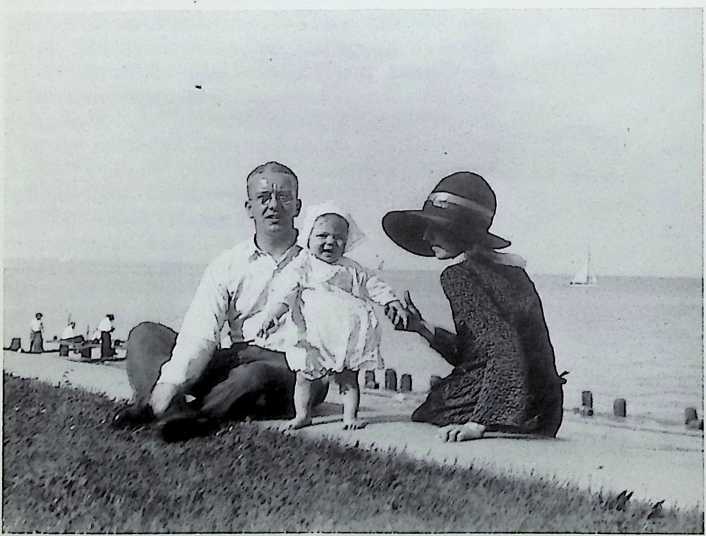

Students and teachers at Milton Preparatory School, Milton, Massachusetts, where Fuller was a pupil from 1900 until 1904. This photograph was taken in his final year. Fuller is standing with the third bicycle from the right. (Below), Fuller, Allegra and Anne in Lincoln Park, Chicago, in 1928the end of the year of silence.

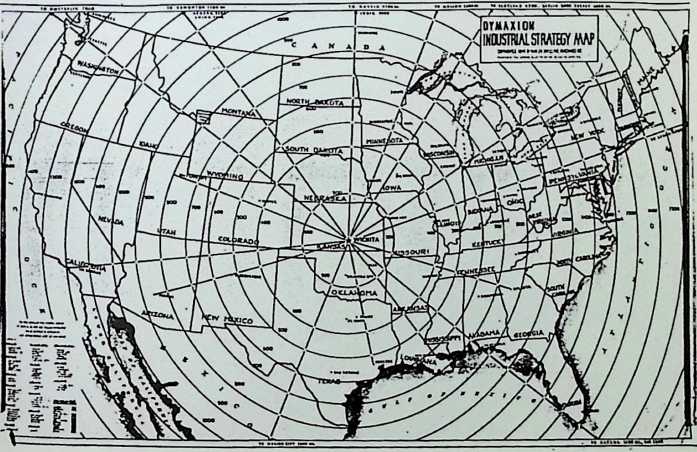

‘Dymaxion’ is the name generally given to the projects with which Buckminster Fuller emerged from his year of isolation, but in fact the word came later and ‘4-D’ coexisted with it for many years. The word ‘Dymaxion’ was invented by the public relations department of the Marshall Field department store in Chicago in 1929. It was allegedly devised by listening to him talk and noting down the words that he most frequently used‘dynamic’ ‘maximum’ and ‘ions’. Fuller liked the name ‘Dymaxion’ and particularly liked the ‘scientific’ way in which it had been discovered. For the next five years it joined ‘4-D’ in the name of the company Fuller formed to develop his inventions and was to be used as a prefix for all his projects for the next 15 years. He even designed a ‘Dymaxion’ logo which was based on a flying fish.

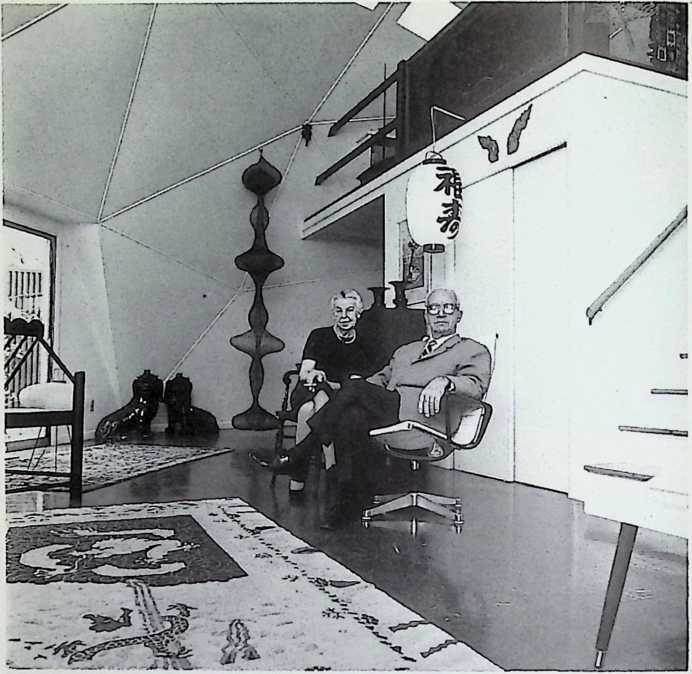

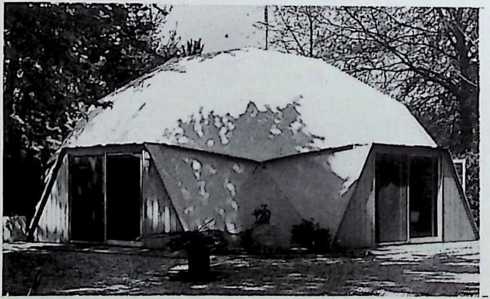

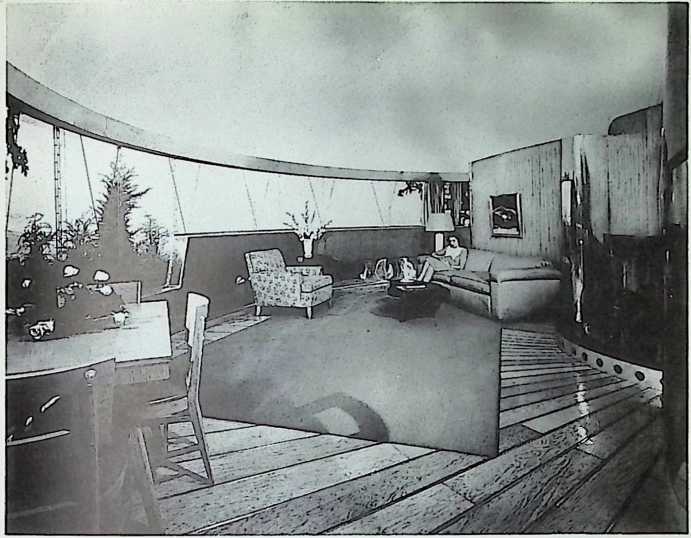

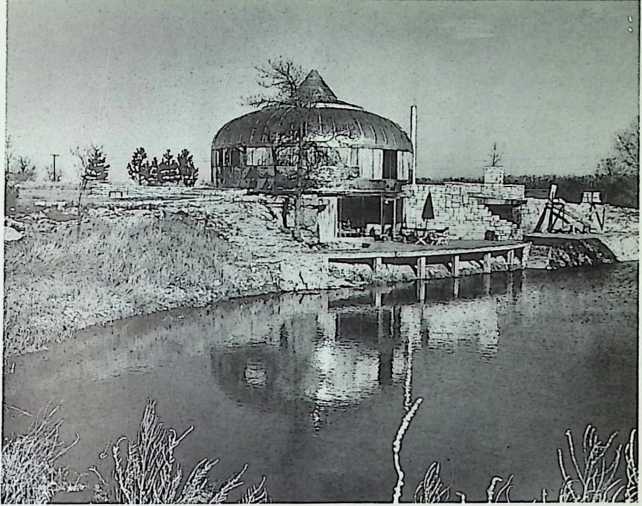

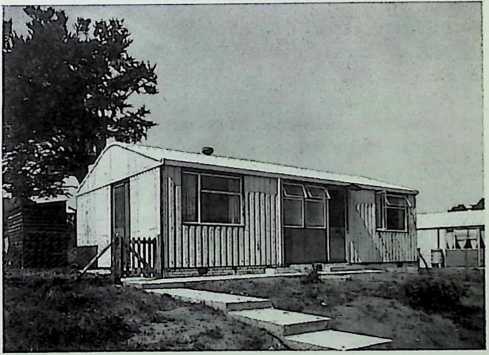

The only home Fuller ever built for himself and his family was a standard plywood Pease dome home, erected at Carbondale in 1966. The interior picture (above) shows Anne Hewlett Fuller and Richard Buckminster Fuller al home in the dome soon alter they moved in.

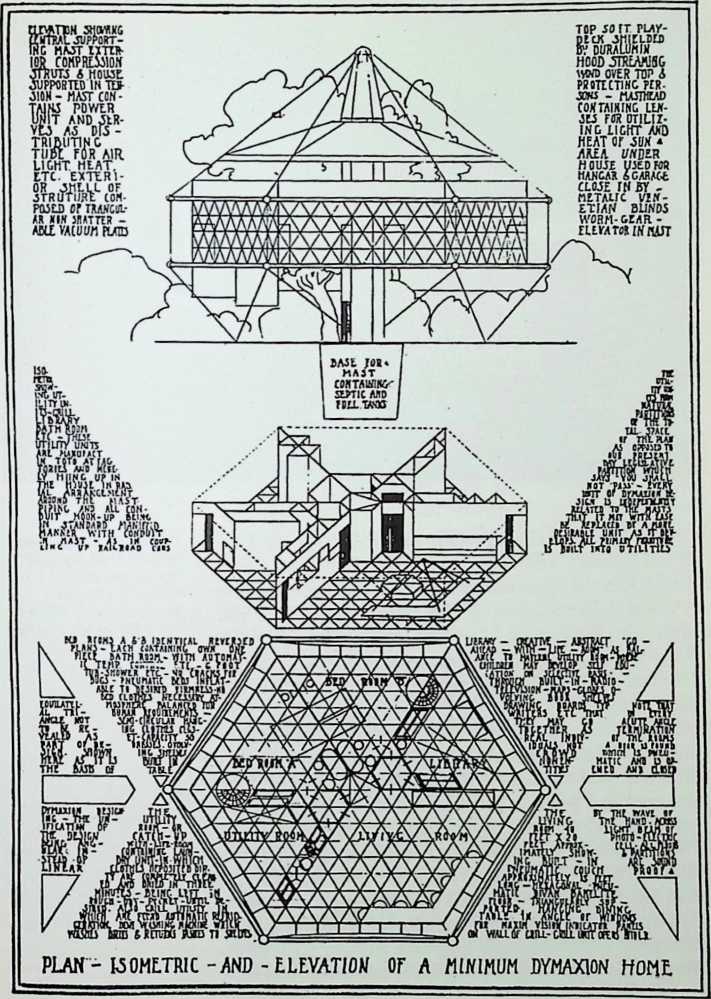

The biggest barriers to a proper evaluation of the Dymaxion projects that emerged from Buckminster Fuller’s time of silence, apart from the congested writing of the seminal text ‘4-D’, which is discussed in the last chapter, is the bewildering number of different stages of development in which the projects have been illustrated ever since.

‘4-D’ itself was a sparsely illustrated pamphlet that was altered and expanded for its subsequent 1970 reprint as ‘4-D Timelock’, so it is unclear whether all the projects bound into the subsequent printing were in fact included in the original. But even from the latter modified printing we can taste the authentic Manifesto flavour. ‘4-D Timelock’ is a rambling yet condensed document, with hasty sketches, bold chapter headings and short chapters, and frequent references to hundreds of pages ‘left out for clarity’ while space apparently remains for endless inconsequential correspondence from relatives and celebrities along the lines of; ‘Dear Mr Buckminster Fuller, I am sorry to say I could not make head or tail of your book’.

The first ‘4-D was in effect a transcript of the halfmad verbal Fuller who burst upon the world in 1928, talking for 16 hours at a stretch. Whether or not it contained a full inventory of the Dymaxion projects is perhaps less important than the fact that the major ones are all now world famous. What can be drawn from it is that after the silent year Fuller emerged a different man. No longer a gregarious travelling businessman, patiently expanding a market for low-cost building blocks, he has become a dynamic theorist, possessed of a seething framework of ideas that he was not to relinquish for the rest of his life.

Historically the best known of these ideas is the

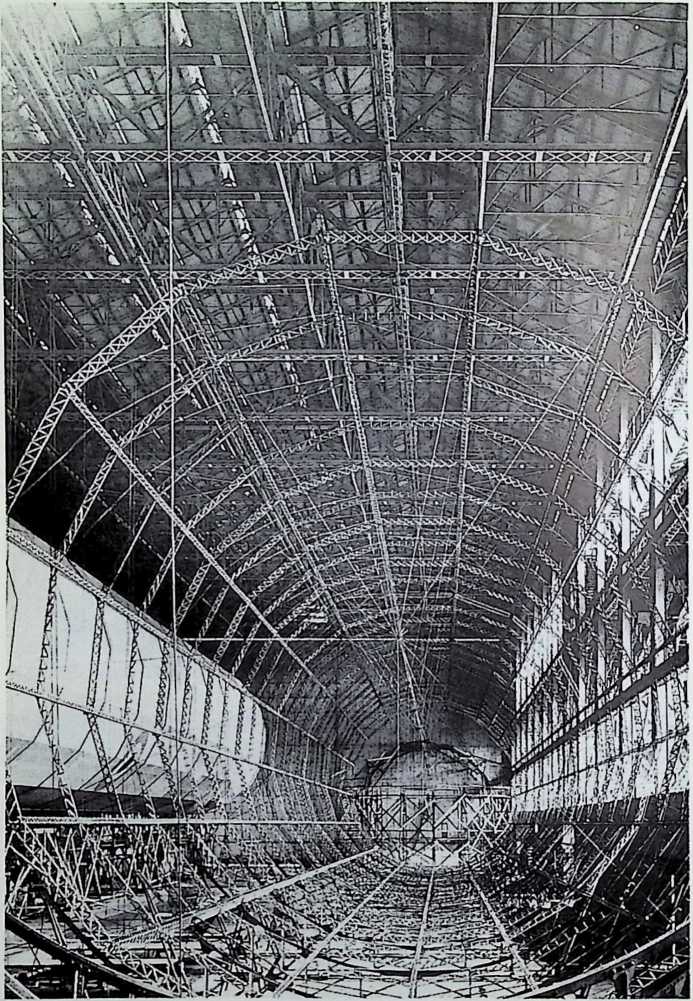

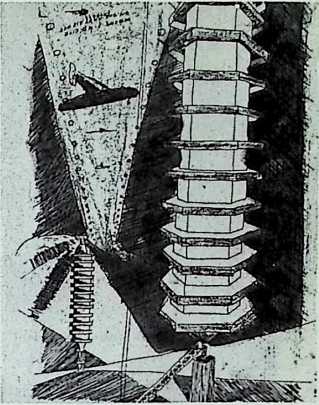

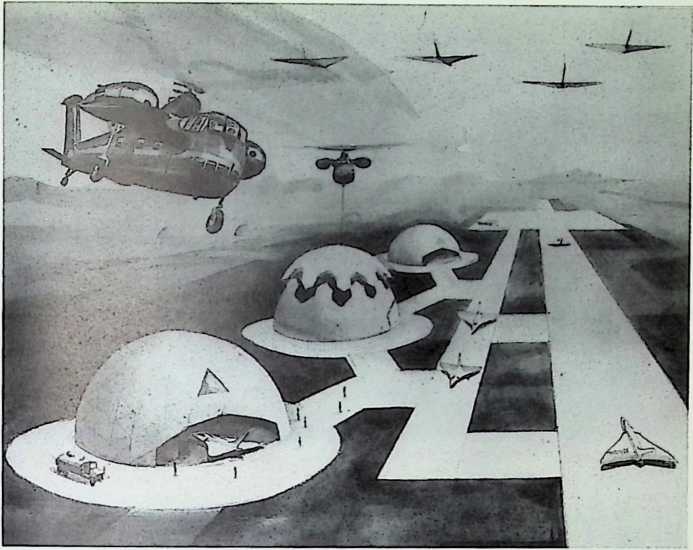

TW-

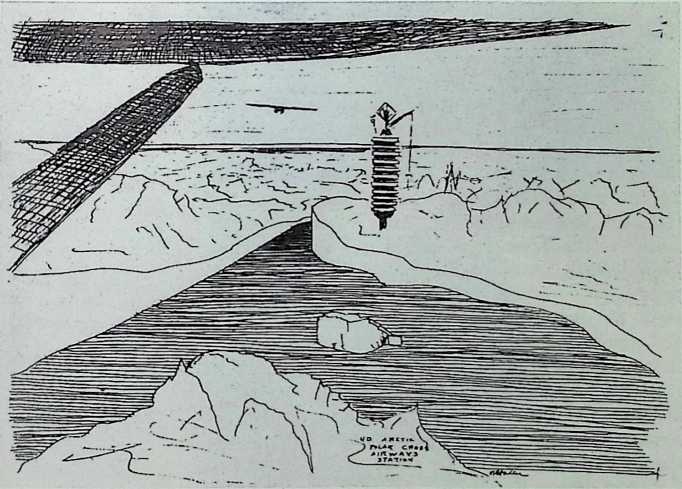

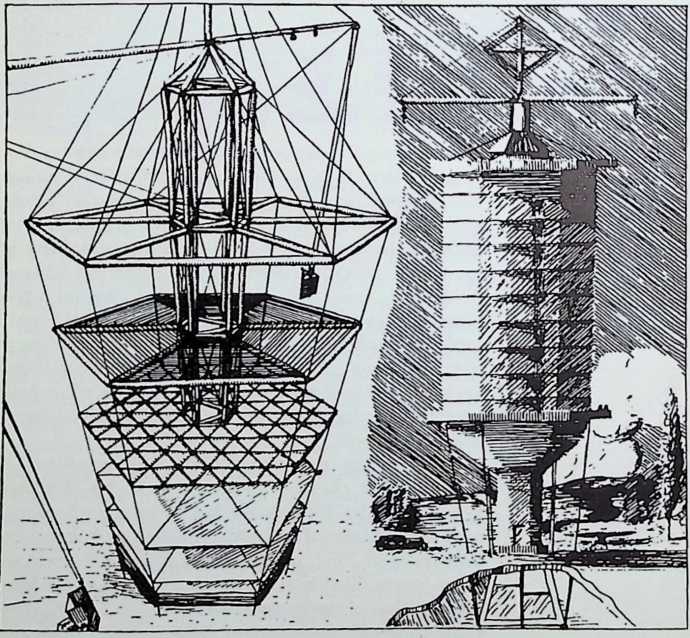

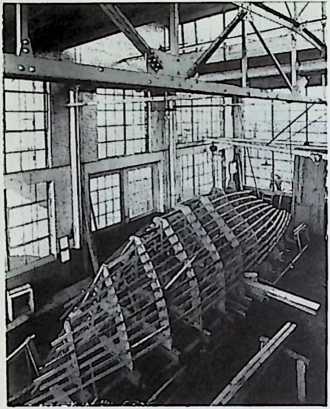

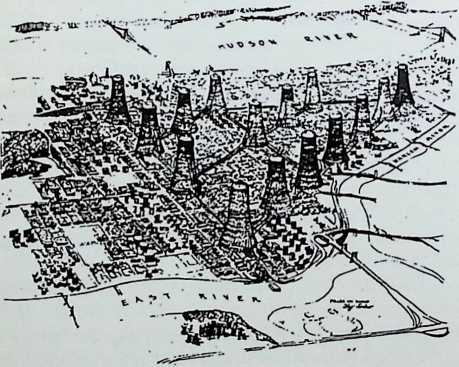

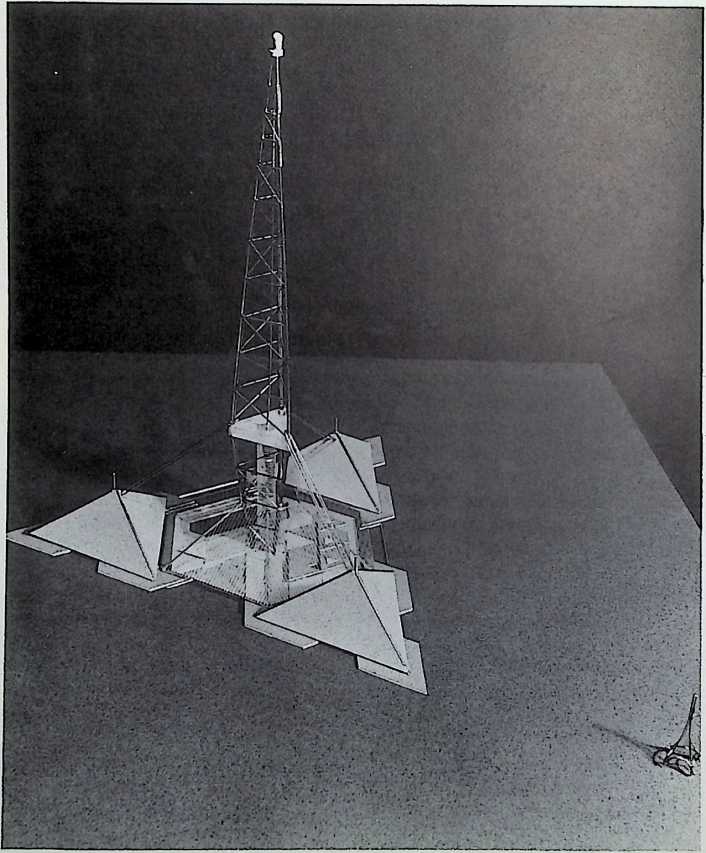

Fuller became obsessed wild the capability of airships during the year of silence. He saw their light but enormously strong tensile tubular construction (left) as ‘no more than a new kind of skyscraper laid upon ils side. Fuller’s own airship based 4D‘ towers were crudely illustrated al first. His drawing ‘Entering a 4 D city on the night air way express (right) shows stacked apartment towers, with cranes and searchlights on their roofs, lining an airport runway. Fuller believed that giant dirigibles like the Graf Zeppelin could transport multi storey ‘4-D’ lowers all over the world. One drawing (below) showed the installation of an airship transported D‘ tower at the North Pole.

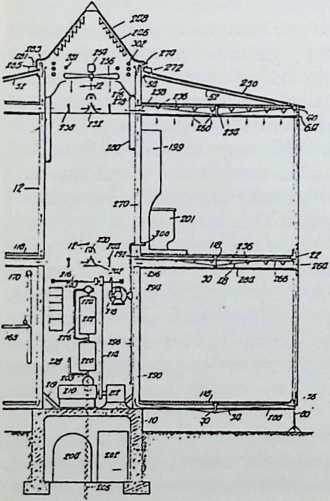

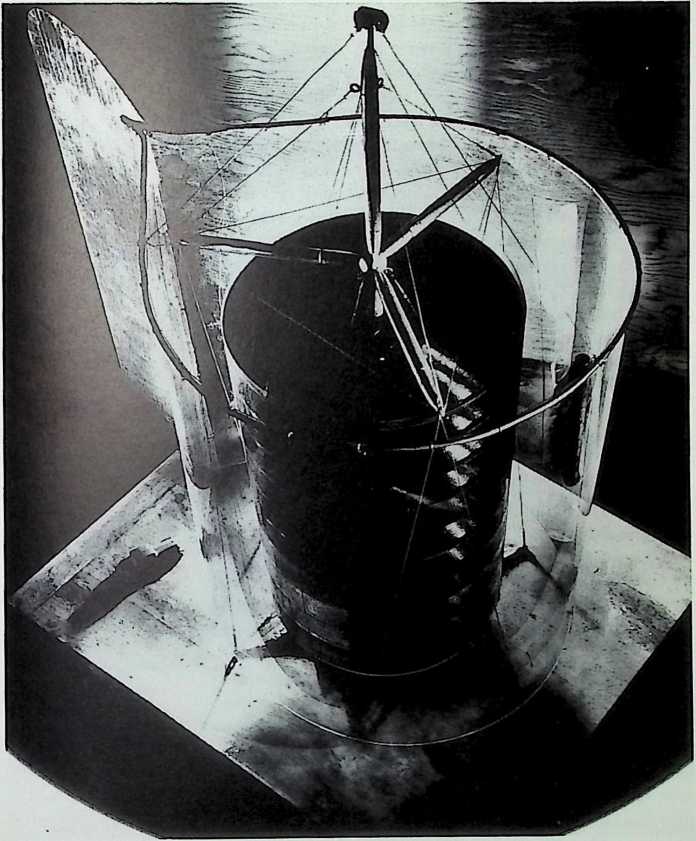

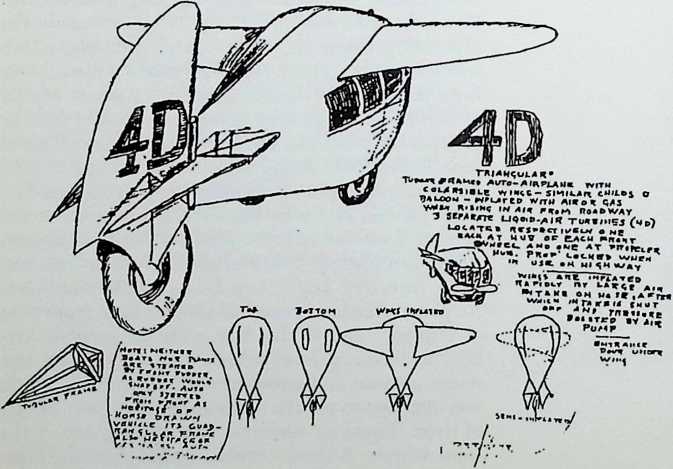

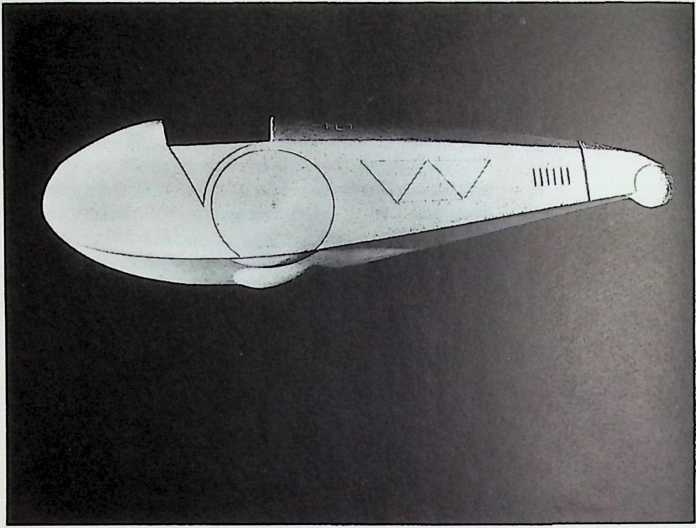

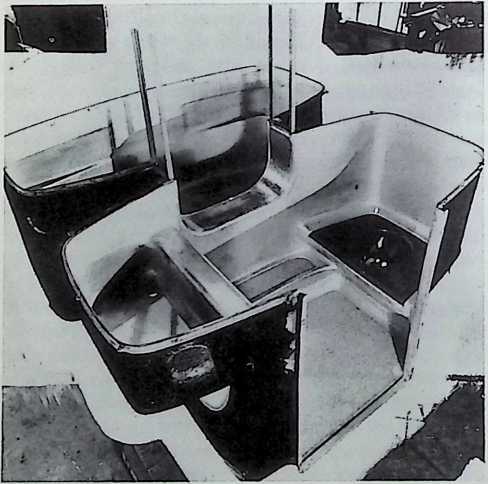

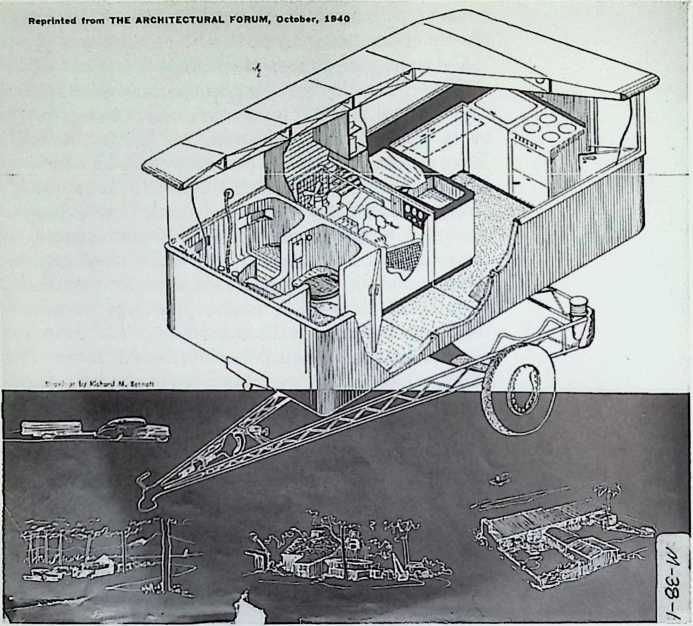

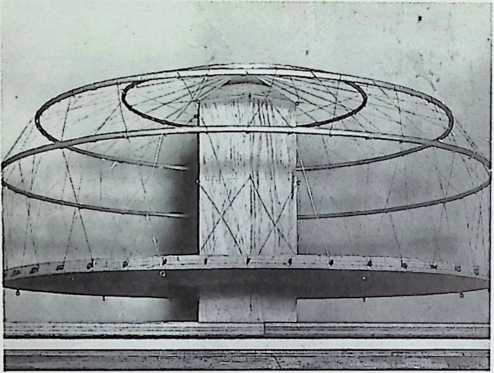

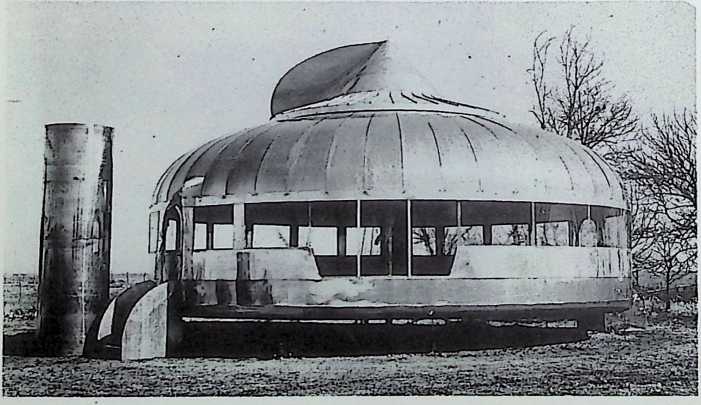

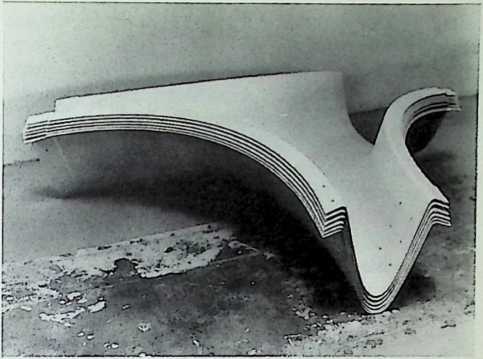

unique combination of functionalism and prefabrication that is enshrined in the familiar image of a mast-supported structure called the Dymaxion House. Next perhaps are the sketches and models of multi-storey ‘4-D’ or ‘Dymaxion’ towers composed of ‘Dymaxion houses’ stacked up to ten or twelve storeys tall. Then there comes the implausible ‘Dymaxion Auto-Airplane, with its inflatable wings. Later these were to be joined by the ‘Dymaxion bathroom’, the ‘Mechanical Wing’ and the converted grain bin-based house called ‘DDU’, or Dymaxion Deployment Unit. Finally there is the last structure in the series which is no longer called Dymaxion, although it was originally christened ‘Dymaxion II’. It is the prototype house for mass production long since renamed ‘Wichita’ after the place in which it was built.

The dates usually assigned to these projects and structures run from 1927 to 1946. The date given for the Dymaxion House is invariably 1927, the same year as the date given to the multi-storey ‘4-D’ towers, which are clearly multiples of the former. The first Dymaxion car was built in 1933, and the ‘DDU’ is variously dated between 1940 and 1944. The ‘Wichita’ house is dated 1944 but the one completed example was assembled from components in 1945.

Accurately dating these projects is difficult, and not only because all their titles are simultaneously those of sketches, drawings, projects, realized prototypes and mass produced articles. For example 1927 is not only the date assigned to the ‘Dymaxion’ house, but also to the first sketches of the ‘4-D Auto-Airplane’, the forerunner of the ‘Dymaxion’ car, as well as the various multi-decked, mast-hung, air deliverable ‘4-D’ apartment towers and their derivatives, the double--D’ tower; the double-helix parking tower, and the suspension wheel office building -all of which are also sometimes described as precursors of the ‘Dymaxion’ house. In the same unsatisfactory way a curiously ‘mediaeval’ drawing exists, also attributed to 1927, that shows the Dymaxion house to scale in elevation, isometric and plan. Even more confusingly there are plaster models of various designs for the ‘ 4-D Auto-Airplane executed

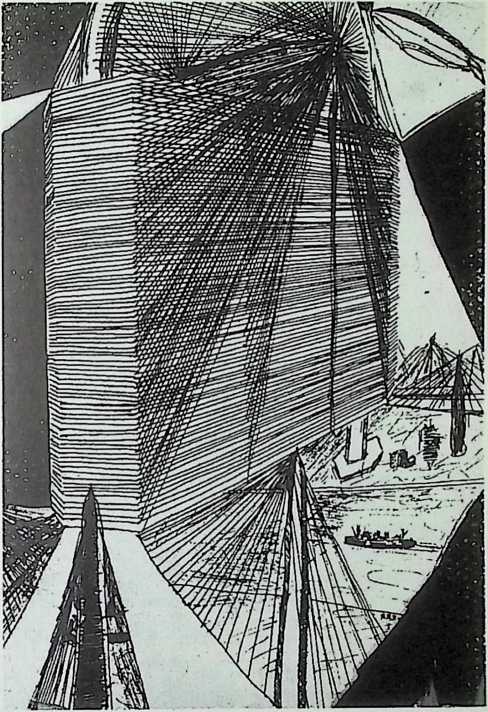

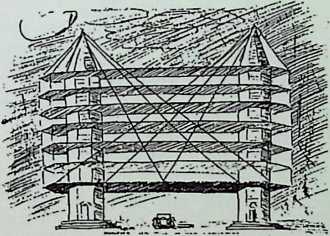

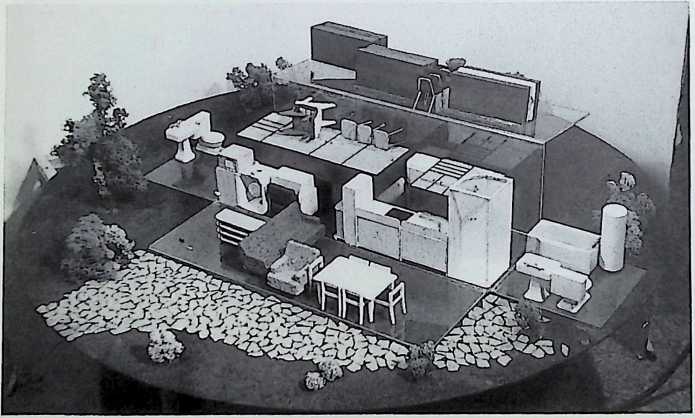

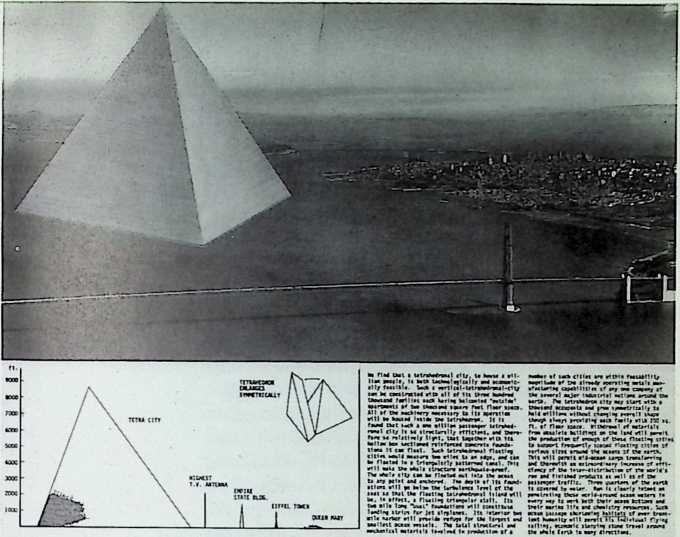

The outpouring of -4 D inventions from the year of silence was not confined Io airship-derived towers. Fuller also sketched a gigantic 100 storey office building whose floors were suspended from the spokes of giant wheel. He also indicated a Double 4-D twin tower office building (below). by Fuller’s friend, the sculptor Isamu Noguchi between 1929 and 1932, which are often seen in photographs beneath models of the ‘Dymaxion’ house. Finally there is the patent application for the ‘4-D’ house, dated 1928, that definitely appears in the pages of ‘4-D but bears only a very limited resemblance to any of the other dwelling drawings or models. Common sense and what we know of Buckminster Fuller’s life and his 1927 breakdown tells us that the first manifestations of the ‘Dymaxion’ series must be the sketches of the world of the future that first appeared in 1929 and may or may not have been included in the hand-bound edition of ‘4-D’ which Fuller circulated privately in 1928principally (and fruitlessly) to bewildered relatives and such notables as Jacob Astor, Bertrand Russell and Henry Ford.

The outpouring of -4 D inventions from the year of silence was not confined Io airship-derived towers. Fuller also sketched a gigantic 100 storey office building whose floors were suspended from the spokes of giant wheel. He also indicated a Double 4-D twin tower office building (below). by Fuller’s friend, the sculptor Isamu Noguchi between 1929 and 1932, which are often seen in photographs beneath models of the ‘Dymaxion’ house. Finally there is the patent application for the ‘4-D’ house, dated 1928, that definitely appears in the pages of ‘4-D but bears only a very limited resemblance to any of the other dwelling drawings or models. Common sense and what we know of Buckminster Fuller’s life and his 1927 breakdown tells us that the first manifestations of the ‘Dymaxion’ series must be the sketches of the world of the future that first appeared in 1929 and may or may not have been included in the hand-bound edition of ‘4-D’ which Fuller circulated privately in 1928principally (and fruitlessly) to bewildered relatives and such notables as Jacob Astor, Bertrand Russell and Henry Ford.

These sketches are simple and almost childish in form, except in their jagged urgency and their consistent use of unusual perspective viewpoints. They show multi-floored apartment towers being carried by airships to distant parts of the globe; rows of the same towers lining aircraft runways, with cranes atop them to raise aircraft to their roofs, and searchlights and wireless antennae prominently displayed. There are also sketches of the interiors of these towers and various derivatives of the same tensile frame structurestwo-mast, cycle wheel and so on.

It is true to say that, apart from their information content, these sketches are executed with remarkably little skill. The lettering accompanying them is poor: so poor that it alone would serve as proof that Fuller never received formal architectural training. Some of them bear the initials ‘RBF’ and some are dated ‘ 1928’. One is called ‘4-D Chicago Home Exposition 1929’. Only one of these drawings, despite the chronology now sanctified by time, is clearly dated 1927. It does not show a Dymaxion house, but is a rough sketch of the world seen from space, with aircraft flying between ‘4-D’ towers located on all continents including the Arctic and the Antarctic. At the bottom of the drawing is the rubric ‘$=TIME’ and an hourglass.

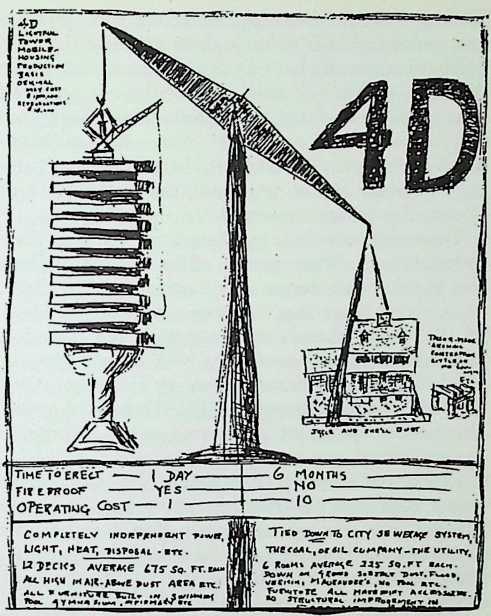

Buckminster Fullers 1928 comparisons between his airship based -D towers and conventional housing were savagely tendentious. The lower was described as completely independent for power, light, heat, sewage disposal, all decks high above dust, fireproof, all furniture built-in, time to erect ■ one day. The conventional six-bedroom house was; tailor made, archaic with little or no sunlight, subject to dust, flood, vermin, marauders, no structural improvement in 5,000 years, lime to erect six months; jiggle and shell bust

Buckminster Fullers 1928 comparisons between his airship based -D towers and conventional housing were savagely tendentious. The lower was described as completely independent for power, light, heat, sewage disposal, all decks high above dust, fireproof, all furniture built-in, time to erect ■ one day. The conventional six-bedroom house was; tailor made, archaic with little or no sunlight, subject to dust, flood, vermin, marauders, no structural improvement in 5,000 years, lime to erect six months; jiggle and shell bust

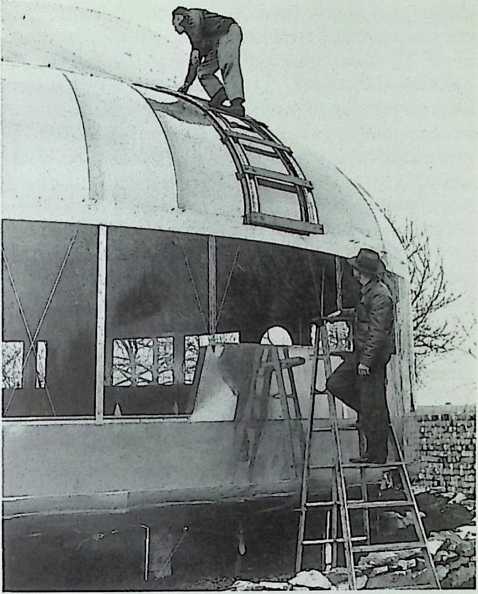

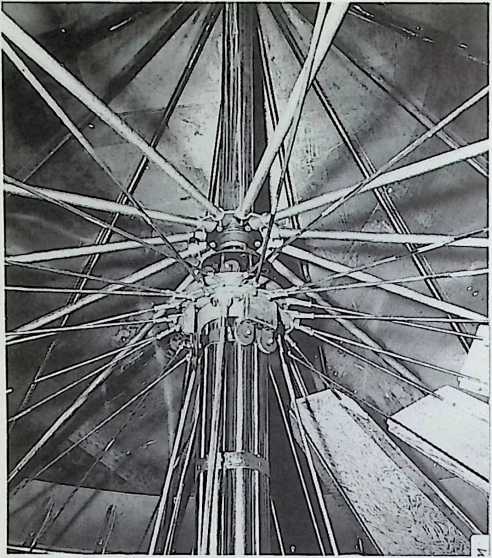

Apart from date written on this drawing, the year 1927 is only retrospectively found in Fuller’s publications, as for example in the captions to the well known photo-series showing the erection of a Dymaxion House model featured in Fifty Years of the Design Science Revolution and the World Game. This document was published 40 years after the event. It was in fact “prepared for free distribution at the joint national meeting of the Operational Research Society and American Astronautical Society, Denver, Colorado, 17 June 1969”.

There is no evidence that the designs for what Fuller called the ‘clean-up’ version of the ‘Dymaxion’ single family house existed before 1929, when a detailed model of it appeared alongside a display of modern furniture in the Marshall Field department store in Chicagofor the first time under the title ‘Dymax-ion’ instead of *4-D’. Nor is there evidence that any of the sketches of the ‘4-D world’ existed before the ‘publication’ of ‘4-D’ itself. Finally there is no proof that any scale drawing of the ‘clean-up’ version of the ‘Dymaxion’ house existed before the unusual ‘mediaeval’ drawing with its patterned lettering that, according to Robert Marks, was published by the Harvard Society for Contemporary Art in May 1929.

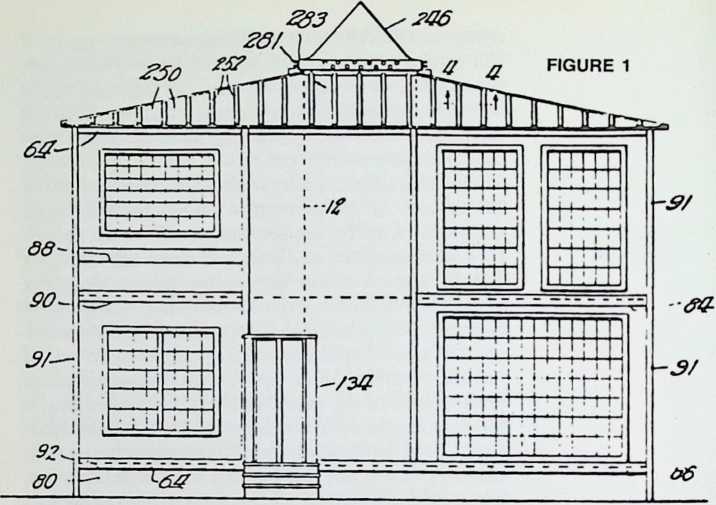

These may seem to be picayune discrepancies to draw attention to in a short account of Buckminster Fuller’s life, but there are deeper uncertainties beneath them, particularly when the ‘4-D’ patent application house of 1928 is introduced into the picture. For there is a shattering contrast between the ‘4-D’ house shown in the US Patent Application made by Fuller on April 1st 1928, and the ‘clean-up’ or ‘1927 Dymaxion house’ that has been portrayed in drawing, model and mockup ever since.

Unlike the ‘clean-up’ Dymaxion, the ‘4-D’ patent house is seldom illustrated. Its appearance is utterly different even though its construction is technically similar in that both are based on a single tubular mast with tension-supported floors. Structurally the most important difference is that the ‘4-D’ patent application house is rectangular in plan, while the ‘clean-up’ Dymaxion is hexagonal, so that all its spans are equal.

Externally the ‘4-D’ patent house is grotesque, betraying once again its designer’s lack of formal architectural training, but in an entirely different way to the lettering that accompanies the published ‘4-D’ sketches. Where the lettering on the sketches is crude, the elevation of the ‘4-D’ house is artless. Its pyramidal metal roof and metal walls are punctuated by enormous windows subdivided into small panes, and the doors, front and back, are both revolving for reasons connected with the operation of the air conditioning and ventilation system. According to the patent application, internally the house was to have pneumatic rubber floors laid over corrugated steel decking. Its external walls were to be formed from suspended sheet metal screens, and its internal partitions from inflatable curtains; ‘not unlike the body protector worn by a baseball catcher’. The decoration of these partitions was described in surprising detail; ‘one side might be a light blue tapestry suitable for a bedroom, and the other side might be a white waterproof oilcloth or linoleum suitable for a bathroom’.

All writers about Fuller in the past have been either too cursory or too partisan to address the important questions raised by the discrepancies between this ‘4-D’ patent application design and what subsequently became known as the ‘Dymaxion’ house. Most fundamentally none has ever asked whether it might have been this ‘4-D’ design that was offered to the American Institute of Architects as a gift in May 1928, and not the futuristic ‘clean-up’ version immortalized by photographs of the model in the Marshall Field exhibition. On the contrary. Most assume that the Marshall Field version of the ‘Dymaxion’ house was patented. It was not. Nor in fact was the ‘4-D’ house. The patent application of April 1st 1928 was rejected and, although Fuller could have pursued the matter like any other applicant, he elected not to.

Given the length and complexity of the full patent application, and the time and effort that would have been involved in producing another one and another set of drawings in time, it is almost certain that it was the archaic-looking rejected ‘4-D’ patent application of April 1st 1928 that Fuller magnanimously offered ‘full proprietary rights in’ to the AIA one month later, and not the ‘clean-up’ Marshall Field version that appeared in the following year. This judgement is confirmed rather than denied by the evasive treatment of the question in Buckminster Fuller’s own book Inventions: the patented works of R. Buckminster Fuller. In this book, published in the year of his death, Fuller shows some drawings and text from the patent application, but intermingled with photographs of the quite different Marshall Field model, with no explanatory distinction between the two.

Somehow Fuller transformed the artless 1928 patent application design into the elegant ‘clean-up’ model. How and when he did it is a mystery that is intensified by the ‘1927’ date generally assigned to the sketches of ‘4-D towers’ that look more like the ‘Dymaxion’ house than the apparently later patent application. Here is a feat as miraculous as the transformation of the bizarre and impractical ‘jet stilt’, inflatable-wing -D Auto-Airplane into the first road-going ‘Dymaxion’ car.

The dramatic evolution of the Dymaxion House April 1928 patent application (left) shows a primitive rectangular metal dwelling with revolving doors and crude elevations. Only section (below, left) shows family resemblance Io later Dymaxion. This was the house design notoriously rejected by lhe American Institute of Architects as a peas-in-a-pod approach. The first drawing of the clean up version (right) which has since become world famous, appeared in this curiously mediaeval form in May 1929.

The best known image ol the Dymaxion house, the model depicted here was first exhibited in a Chicago department store in 1929 and then al the Chicago Arts Club in 1930.

In fact the ‘Dymaxion’ house transformation is even more miraculous than the ‘Auto-Airplane’ metamorphosis because, in the latter case, we know that another individual was involved. He was the well-known aircraft and yacht designer Starling Burgess, who Fuller first met in a hotel in New York City in August 1932 and talked to for four and one half hours. Burgess was a key figure in the genesis of the Dymaxion car. He developed Fuller’s analogies between the shapes and steering mechanisms of boats and fish and motor vehicles, and he knew as much as anyone in the world at that time about streamlining and tension structures. Burgess not only designed seaplanes, but three Americas Cup defenders, including the 1930 victor Enterprise, with its revolutionary $50,000 duralumin mast and perforated duralumin boom, a triangulated rig that saved over one ton in weight over the steel used by the British challenger.

It is a matter of record that, after their meeting, Burgess went to work with Fuller at the ‘4-D Dymax-ion Company’ in Bridgeport, Connecticut, where the Dymaxion cars were built. It is also recorded, by Fuller himself, that Burgess calculated the dimensions of the central mast for the superimposed floors of the proposed ten-storey Dymaxion skyscraper, and Burgess who designed the aerodynamic screen that enclosed it. But this was not until 1932. The assistance of Burgess in a similar but earlier transformation of the ‘4-D’ patent application dwelling into the now famous ‘cleanup’ version of the Dymaxion house can probably be ruled out on chronology alone.

There are of course other possibilities. Fuller’s father-in-law, James Monroe Hewlett, might have exercised a benevolently intended but unfortunate influence over the preparation of the 1928 ‘4-D’ patent application and attempted to render its appearance more conventional. Hewlett had, after all, jointly with Fuller, already filed one patent applicationfor the ‘Stockade’ building system that was granted in 1927. Alternatively the ‘clean-up’ model may have started out as an unclad structural model of the patent application house. Or perhaps another figure, possibly the unnamed ‘wordsmith’ who invented the term ‘Dymaxion’ at the behest of the Marshall Field publicity department, played a part. ‘Dynamic’ ‘Maximum’ and Tons’ are all we know about this man, but anyone who could invent a term like ‘Dymaxion’ must have been extraordinarily capable.

Whatever the explanation for this minor mystery, it is a fact that the first publication of the ‘clean-up’ version of the Dymaxion house in a professional architectural journal was not in 1928 or 1929, but three years later in 1932, in the March edition of Architectural Forum. Two months later it appeared in the May 1932 edition of the magazine Shelter with Fuller’s own Corbusier-style collection of design influences for the

Dymaxion house: lighthouses, water tanks, even a piggery. Six months later Fuller’s len storey ‘Dymaxion’ skyscraper with its aerodynamic cowling • radically different to the 1928 4D sketches as a result of Burgess’s structural and streamlining skillsmakes its first appearance in the November 1932 edition of Shelter.

However the ‘4-D’ metamorphosis was carried out, its results were immediate and beneficial. From the ‘clean-up’ version onwards several models of the ‘Dymaxion’ house were constructed for exhibition and Fuller began to lecture on the subject of a world prefabricated housing industry using ‘4-D’ or ‘Dymaxion’ designs.

later improvements to the originally crude and unstable 4D towers followed the progress ol lhe Dymaxion house. 1930 Chicago drawings (below) show suspended floors and triangulated central mast. 1932 Starling Burgess version shows tapered duralumin yacht spar construction with more convincing and broader based shrouds, as well as transparent aerodynamic shield to reduce heat loss (right).

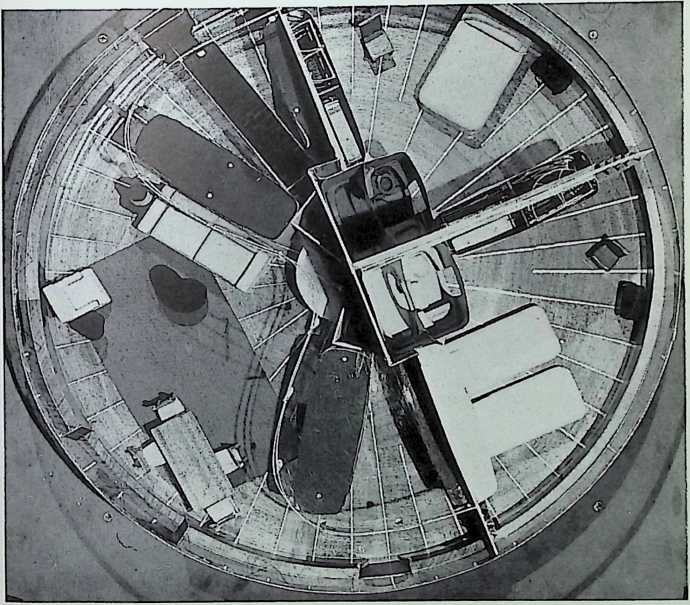

In 1930 a model of the ‘Dymaxion’ house was shown at the Chicago Arts Club and there was talk of a full-sized example being built for the 1933 World’s Fair. By 1930 the specification of the house had changed from the eccentric arrangements described in the patent application. Not only was it now described as ‘deliverable in 24 hours’ when ‘installed and serviced by men trained in their work’, but it was said to ‘eliminate drudgery, selfishness, exploitation, politics and centralized control’, and safeguard against ‘flood, fire, tornado, electrical storms, earthquakes and hurricanes’. The construction of the dwelling has become very advanced too. Instead of metal… ‘For walls, windows and ceilings: Casein, a transparent, translucent opaque sheeting made from vegetable refuse. The bathrooms are cast in a single sculptural unit of casein and inserted into the house. For doors: Silver balloon silk inflatable and so dustproof. For shelter covers: Duraluminan alloy of aluminium used hem in panels or rollers. For floors: Inflatable rubber units. For light: An oil engine both warms the house and illuminates it by a system of mirrors through the translucent walls.’

The price of this version of the Dymaxion housewhen in production was estimated at $1,500approximately £11,000 at 1989 values at a time when new houses sold for $8,000. In the event, when asked by the organizers of the 1933 World’s Fair what it would cost to build a prototype for production, Fuller honestly replied that the figure would be in excess of $100 million, because it had cost Henry Ford $43 million to develop the Model-A, the successor to the famous ModelT car. In the end the World’s Fair organizers built a non-mast-supported ‘house of tomorrow’ with some superficial resemblance to the Dymaxion House instead.

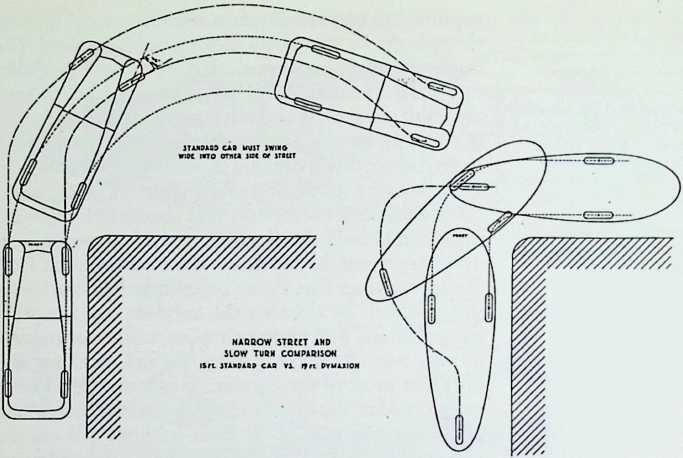

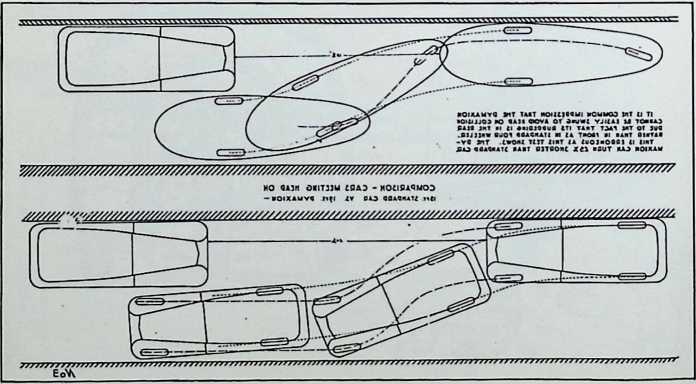

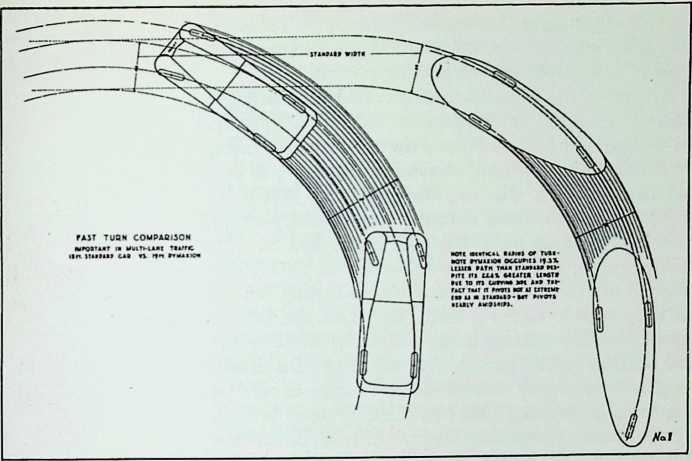

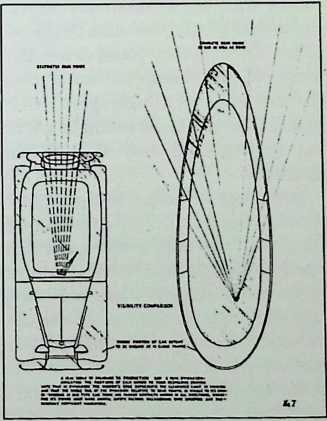

¶ dymaxion cars

Since I was intent on developing a high-technology dwelling machine that could be air delivered to any remote, beautiful country site where there might be no roadways or landing fields for airplanes, I decided to try to develop an omni-medium transport vehicle to function in the sky, on negotiable terrain, or on water • to be securely landable anywhere, like an eagle’.

Buckminster Fuller 1983

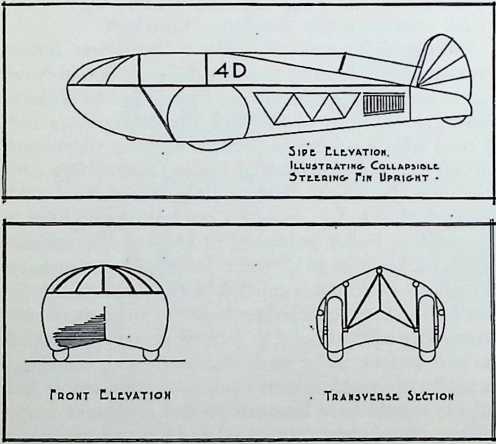

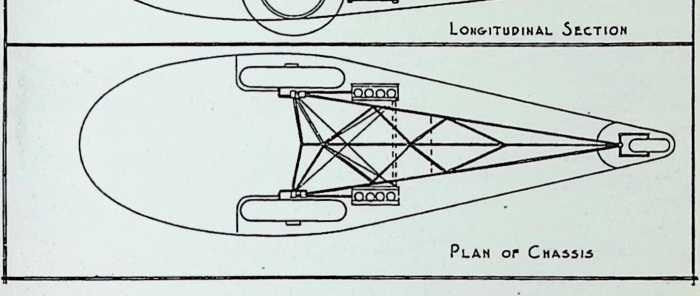

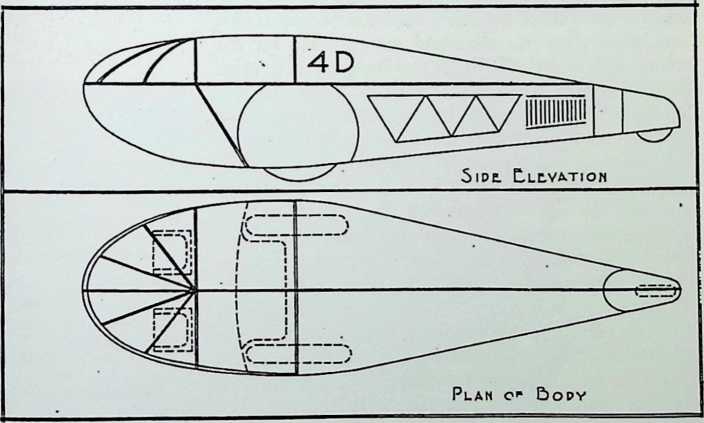

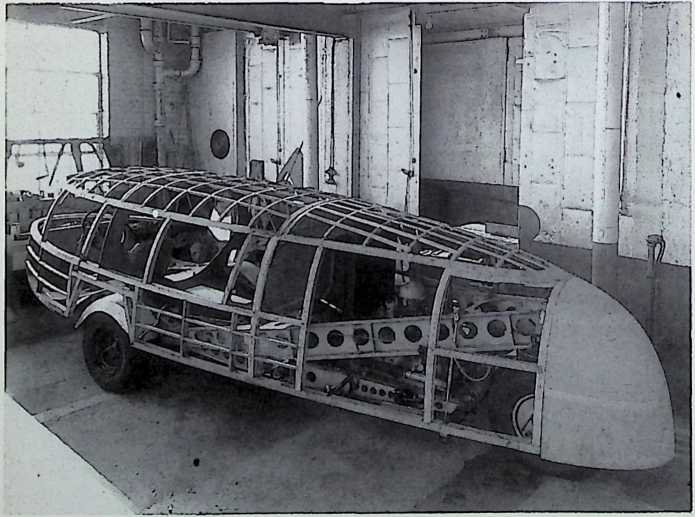

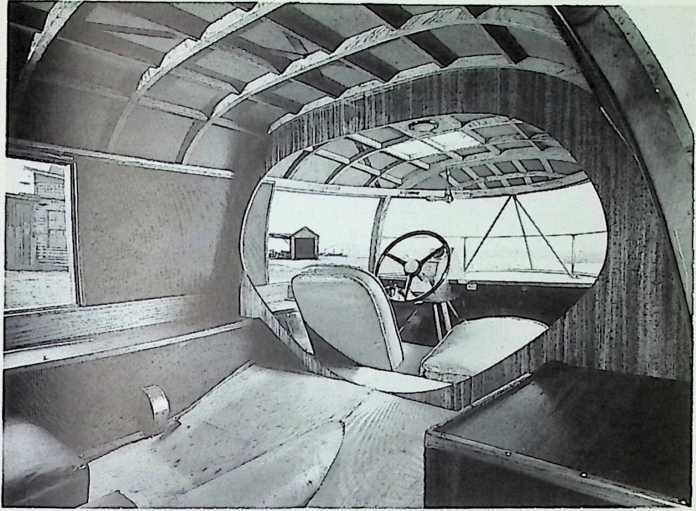

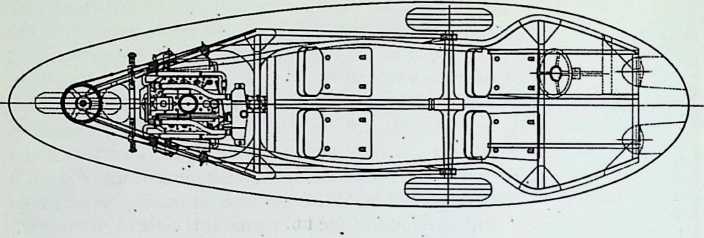

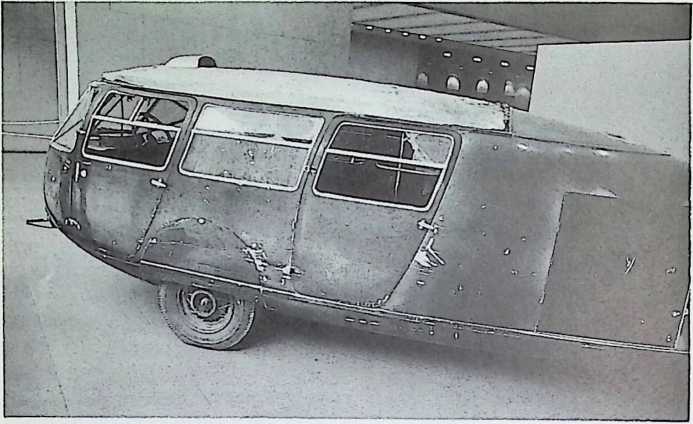

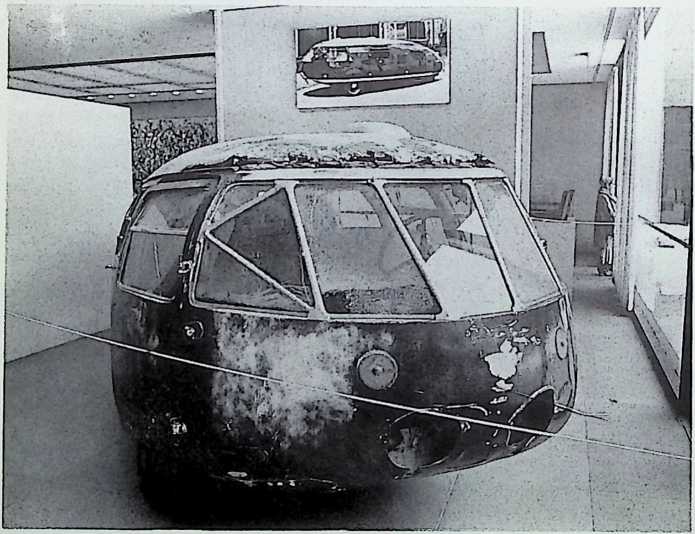

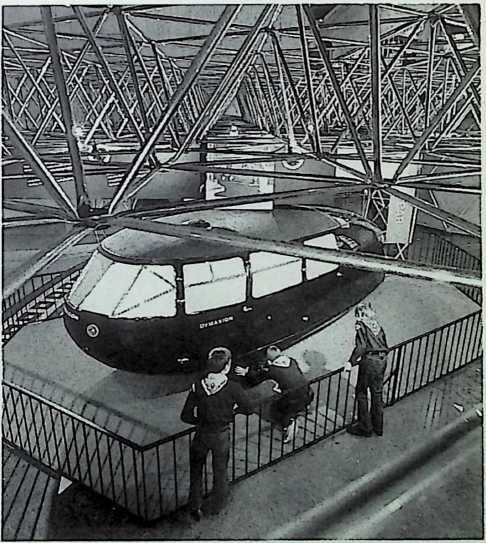

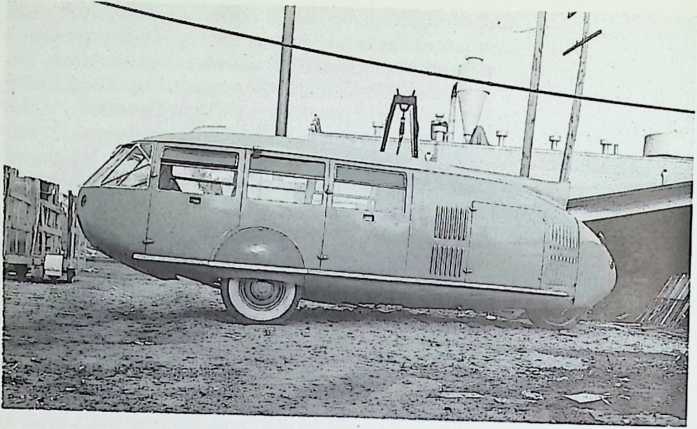

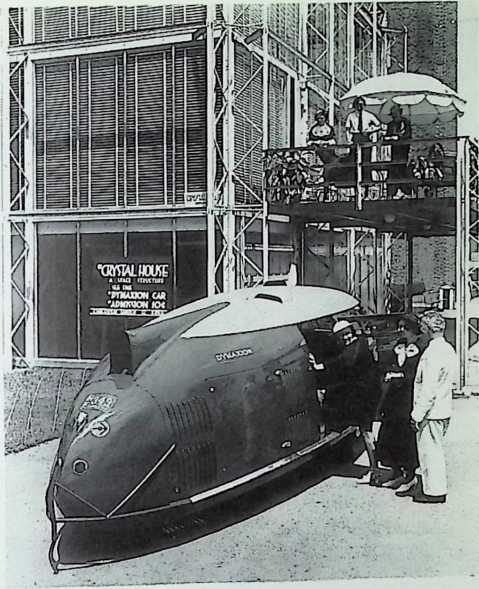

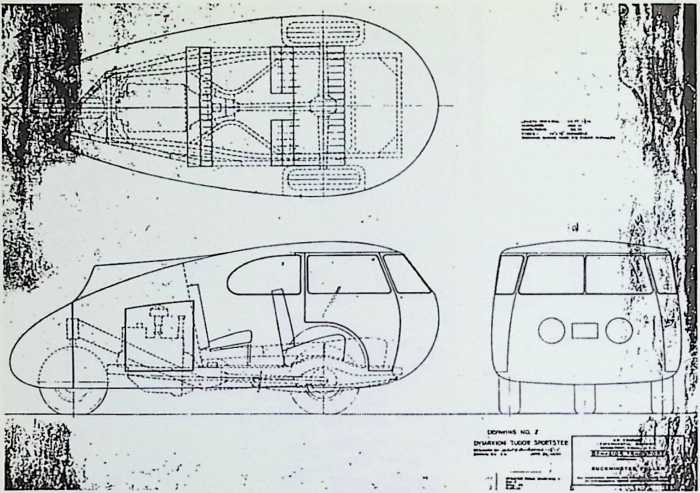

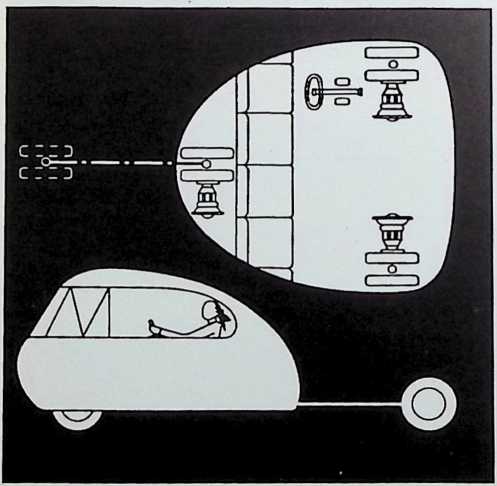

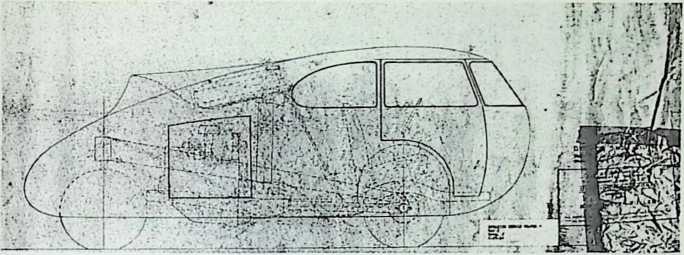

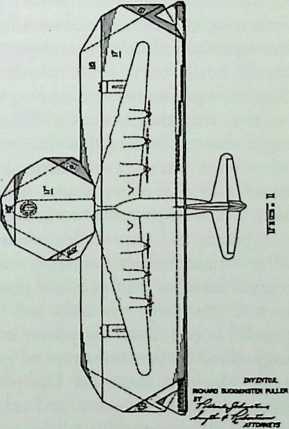

Buckminster Fuller and Starling Burgess built three Dymaxion cars during 1933 and 1934. And unlike the Dymaxion house and the Dymaxion towers, which were destined to remain paper and model projects, there is no doubt about their appearance, existence or date of birth. Although they never intentionally left the ground, the principles underlying their design derived from Fuller’s ‘4-D Auto-Airplane’ sketches of 1928, and the subsequent plaster Noguchi models that were lovingly painted by Fuller himself for exhibition in the parking areas beneath the model Dymaxion houses.

The aeroplane ancestry of the Dymaxion cars was plain from the beginning. In his 1928 ‘4-D AutoAirplane’ sketches Fuller had showed little more than a ‘teardrop’ aircraft fuselage with an inverted vee- bottom, recessed front wheels and a combined rear steering wheel and aerodynamic rudder. This vehicle was intended to use the roads under the power of two of three ‘liquid air turbines’, each driving one of the front wheels. A third ‘turbine’ would drive the nose

mounted propeller for flight. The transport would take to the air by using its forward motion to inflate pneumatic wings, with the pressure topped up by an air pump.